Nylon Conduit Connector SM

What Are Conduit Connectors?

Conduit connectors join tubes that keep wires safe. They help us make paths for wires in homes, shops, and big places. At CAGLAND, we make top parts for your wire needs.

Our Plastic Conduit Connectors

We make strong parts for wire paths. Our parts come in two main types:

- PVC parts that don’t rust

- Brass parts that last a long time

Types We Make

We have many kinds of parts:

- Couplings – join two tubes

- Elbows – make turns in wire paths

- T-connectors – split one path into two

- Adapters – join different size tubes All our parts keep wires dry and safe!

What Makes Our Parts Special

| Good Things | What This Means For You |

|---|---|

| Strong PVC or Brass | Parts won’t break in sun, rain or cold |

| Tight Seals | No water gets in to hurt wires |

| Easy to Put On | You don’t need big tools |

| Many Sizes | Fits all tube sizes from ½” to 4″ |

| Safe to Use | Meets all wire rules (NEC and UL) |

Where to Use Our Parts

Our parts work well in many places:

Big Work Places

- Keeps wires safe in wet spots

- Works in hot and cold spots

- Stops bad stuff like oil from hurting wires

Outside Jobs

- Stays strong in sun and rain

- Keeps wires dry when it rains

- Works well when put in ground

Shops and Malls

- Looks neat in big rooms

- Helps keep many wires neat

- Fits with air and cool systems

Home Use

- Easy to put in

- Keeps kids safe from wires

- Looks neat on walls

More Things We Make

We don’t just make **. We also make:

- Plastic water proof cable gland – Stops water from touching wires

- Metal water proof cable gland – Strong parts that keep water out

- Multi hole cable gland – For when you need many wires in one spot

- Junction box – Safe spots to join wires

- Cable gland adaptors – To make parts fit just right

- Reducers & enlargers – To join big tubes to small tubes

Why Pick Our Parts?

Made Strong

Our parts don’t break fast. They stay good in hot sun, cold snow, wet rain, and near bad stuff that can hurt wires.

Easy to Use

You don’t need big tools or to be very strong. Our parts go on fast and stay on right.

Fits All Needs

Need small parts? Big parts? Turns? Splits? We have it all!

Keeps Rules

Our parts follow all the big wire rules like NEC and UL. This means they’re safe to use.

Looks Good

Our parts look neat on walls and don’t stand out too much.

Size Chart

| Size | Best For | Fits With |

|---|---|---|

| ½” | Home use | Small wires |

| ¾” | Small shops | Light use |

| 1″ | Big homes | Main wire runs |

| 1½” | Shops | Many wires |

| 2″ | Big shops | Big wire runs |

| 3″ | Wet spots | Lots of big wires |

| 4″ | Big work spots | Most wires you can think of |

How to Pick the Right Part

- Check the size of your tubes

- Pick the type you need (turn, join, split)

- Pick PVC or brass based on where it goes

- Check if you need tight seals for wet spots

How to Put Our Parts On

It’s so easy:

- Cut the tube straight

- Clean the tube end

- Push the part on the tube

- Turn to make it tight

- Check that it’s on right Even kids can learn to do it!

What Makes Our PVC Parts Great

- Won’t rust or break down

- Costs less than metal parts

- Light and easy to move

- Can be white or gray to match walls

- Stops fire from moving on wires

- Keeps bad stuff out

What Makes Our Brass Parts Great

- Very strong for tough spots

- Lasts a very long time

- Looks nice and shiny

- Can take heat and cold

- Good for places with lots of buzz (EMI spots)

- Keeps tight seal for years

We Can Make Parts Just For You

Need a part we don’t have? We can make it! Our team makes custom parts for you. Tell us:

- What size you need

- Where it will go

- What it needs to do

- How many you want We’ll make just what you need!

Safe Wire Ways

Our parts help keep wires safe. This is good for:

- Stops fires from bad wires

- Keeps kids from touching wires

- Makes sure wire paths last long

- Helps fix wire spots fast if they break

Why CAGLAND?

We know wire paths. We make the best parts to keep them safe. When you buy from us, you get:

- Parts that work right

- Parts that last long

- Help when you need it

- Fast sends of what you buy

- Fair costs

Get Help From Us

Need help with wire paths? Just ask us. We can help you pick:

- What parts you need

- How many to get

- What size is best

- How to put them on

Join Our Big Work Team

We work with big shops and work spots. If you need lots of parts, we can help. We give:

- Price cuts for big buys

- Fast sends to work spots

- Ways to track your buy

- Just-in-time sends

- Stock help

Get Your Wire Path Parts Now

Ready for the best conduit connectors? Check our full prensaestopas shop now. We have all you need to keep wires safe and neat.

Call us: +86 137 7301 8938

Email us: [email protected]

CAGLAND – Keeping Wires Safe

Consulta

Especificación

Product Specification

| Product Name | SM-G series plastic hose waterproof joint |

| Product Material | Using PA nylon |

| Thread specifications | German system (PG)/metric system (M)/imperial system (G). |

| working temperature | -40°C~+110°C |

| Product color | Black (special colors can be customized). |

| Product Features | The internal lock buckle and special design of the body allow for easy insertion and removal without the need for tools |

| usage method | YDT-SM-G type hose connector is a hose matching product that can be connected to the equipment box or to electric equipment with internal threads at the inlet and outlet according to the selected thread. Simply insert the hose into the interface and lock it. |

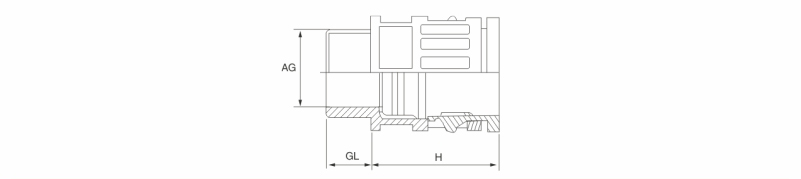

| Product specifications | Please refer to the specification and size diagram for specific models |

| Technical Parameters (Combined PG/M/G Thread Series) | ||||||

| PG Thread Series | ||||||

| Modelo | Suitable Pipe | Thread Spec | Outer Ø (mm) | Inner Ø (mm) | GL (mm) | H (mm) |

| SM-G-PG7 | AD10.0 | PG7 | 12.3 | 6.5 | 11.5 | 18 |

| SM-G-PG9 | AD13.0 | PG9 | 15 | 10 | 11.5 | 19 |

| SM-G-PG11 | AD15.8 | PG11 | 18.4 | 12 | 12 | 23 |

| SM-G-PG13.5 | AD15.8 | PG13.5 | 20.2 | 14.3 | 12 | 25 |

| SM-G-PG13.5 | AD18.5 | PG13.5 | 20.2 | 14.3 | 12 | 25 |

| SM-G-PG16 | AD21.2 | PG16 | 22.3 | 17 | 13 | 27 |

| SM-G-PG21 | AD28.5 | PG21 | 28 | 23 | 13 | 33 |

| SM-G-PG29 | AD34.5 | PG29 | 36.7 | 29 | 15 | 35 |

| SM-G-PG36 | AD42.5 | PG36 | 46.7 | 36 | 15 | 38.5 |

| SM-G-PG48 | AD54.5 | PG48 | 59 | 53 | 16 | 39 |

| M Thread Series | ||||||

| Modelo | Suitable Pipe | Thread Spec | Outer Ø (mm) | Inner Ø (mm) | GL (mm) | H (mm) |

| SM-G-M12 | AD10.0 | M12×1.5 | 12 | 6.5 | 10 | 22.5 |

| SM-G-M12 | AD13.0 | M12×1.5 | 12 | 8 | 10 | 26 |

| SM-G-M16 | AD13.0 | M16×1.5 | 16 | 10 | 10 | 23 |

| SM-G-M18 | AD13.0 | M18×1.5 | 18 | 10 | 11.5 | 23 |

| SM-G-M20 | AD13.0 | M20×1.5 | 20 | 10 | 11.5 | 23 |

| SM-G-M16 | AD15.8 | M16×1.5 | 16 | 12 | 10 | 24 |

| SM-G-M18 | AD15.8 | M18×1.5 | 18 | 12 | 11.5 | 24 |

| SM-G-M20 | AD15.8 | M20×1.5 | 20 | 12 | 11.5 | 24 |

| SM-G-M20 | AD18.5 | M20×1.5 | 20 | 14.3 | 12 | 25.5 |

| SM-G-M20 | AD21.2 | M20×1.5 | 20 | 17 | 13 | 27 |

| SM-G-M24 | AD21.2 | M24×1.5 | 24 | 17 | 13 | 27 |

| SM-G-M25 | AD21.2 | M25×1.5 | 25 | 17 | 13 | 27 |

| SM-G-M25 | AD25.0 | M25×1.5 | 25 | 20 | 14 | 30 |

| SM-G-M25 | AD28.5 | M25×1.5 | 25 | 23 | 20 | 34 |

| SM-G-M27 | AD28.5 | M27×2.0 | 27 | 23 | 14 | 34 |

| SM-G-M30 | AD28.5 | M30×2.0 | 30 | 22 | 11 | 33 |

| SM-G-M32 | AD28.5 | M32×1.5 | 32 | 25 | 14 | 33 |

| SM-G-M32 | AD34.5 | M32×1.5 | 32 | 29 | 20 | 36 |

| SM-G-M36 | AD34.5 | M36×2.0 | 36 | 29 | 14 | 36 |

| SM-G-M40 | AD34.5 | M40×1.5 | 40 | 29 | 15 | 38.5 |

| SM-G-M40 | AD42.5 | M40×1.5 | 40 | 36 | 15 | 38.5 |

| SM-G-M48 | AD42.5 | M48×2.0 | 48 | 36 | 15 | 38.5 |

| SM-G-M50 | AD54.5 | M50×1.5 | 50 | 38 | 16 | 39 |

| SM-G-M60 | AD54.5 | M60×2.0 | 60 | 53 | 16 | 39 |

| SM-G-M63 | AD54.5 | M63×1.5 | 63 | 53 | 16 | 39 |

| G Thread Series | ||||||

| Modelo | Suitable Pipe | Thread Spec | Outer Ø (mm) | Inner Ø (mm) | GL (mm) | H (mm) |

| SM-G-G1/2″ | AD21.2 | G1/2″ | 20.9 | 17 | 13 | 27 |

| SM-G-G1/2″ | AD25.0 | G1/2″ | 20.9 | 20 | 14 | 30 |

| SM-G-G3/4″ | AD28.5 | G3/4″ | 26 | 23 | 14 | 34 |

| SM-G-G1″ | AD34.5 | G1″ | 33 | 29 | 14 | 36 |

Preguntas frecuentes sobre prensaestopas

No hemos establecido un MOQ mínimo, personalizamos los productos según las necesidades del cliente. En teoría, podemos cumplir con los diferentes requisitos de MOQ de los clientes, pero diferentes MOQ tendrán diferentes costos.

Normalmente, nuestro tiempo de entrega es de 1 a 2 semanas para la producción por lotes. Para casos urgentes, podemos mejorarlo en 3~7 días.

Necesitamos la dimensión, el color, el hilo, el material, la certificación y más aplicaciones serán útiles.

Contamos con certificados CE, TUV y UL.

Ciertamente, podemos proporcionarle muestras estándar gratuitas según sus requisitos.