DWJ Metal Hose Connector Series 90°

What Are Flexible Metal Conduit Connectors?

Flexible Metal Conduit Connectors join metal tubes that hold wires. They keep the wires safe. Our connectors are strong. They last a long time. They meet all the rules for wire safety.

Why Choose Our Conduit Connectors?

- Safe: All our parts pass UL and NEC tests

- Strong: Made from good metals that don’t rust

- Easy to Use: Quick to put in

- Fit All Sizes: We have sizes from 3/8″ to 4″

- Keep Water Out: Tight seals stop water, dust, and oil

Types of Conduit Connectors We Make

We make many kinds of connectors:

1. Liquid-Tight Connectors

These keep all water out. They work well outside. They also keep out:

- Oil

- Dust

- Mud

- Snow

- Rain

Our metal water proof cable gland also helps keep water away from wires.

2. Anti-Static Connectors

These stop sparks. They are safe in places that might blow up. They have:

- Copper parts inside

- No gaps for sparks

- Good ground paths

3. Direct Burial Connectors

You can put these in the ground. They don’t rust. They work in:

- Wet dirt

- Wet sand

- Hard rocks

- Wet cement

Where to Use Our Connectors

Our conduit connectors work in many places:

| Place | Why Our Connectors Work There | What They Do |

|---|---|---|

| Factories | Stand up to shaking machines | Keep wires from breaking |

| Outside | Don’t rust in rain or sun | Keep wires dry |

| Cold Places | Work when it’s very cold | Stay strong in ice |

| Hot Places | Don’t melt when hot | Keep shape in heat |

| Wet Areas | Keep water out | Stop rust and shorts |

| Farms | Don’t break when hit | Protect from animals and tools |

For wet spots, try our plastic water proof cable gland too.

Connector Sizes We Have

We make all these sizes:

- 3/8 inch

- 1/2 inch

- 3/4 inch

- 1 inch

- 1-1/4 inch

- 1-1/2 inch

- 2 inch

- 3 inch

- 4 inch

Big or small, we have what you need!

Material Choices

Our connectors come in:

- Steel: Very strong

- Metal with Zinc: Stops rust

- Metal with Paint: Looks nice

- Aluminum: Light but strong

Safe and Up to Code

All our parts meet these rules:

- UL Listed (Fire safe)

- NEC Articles 350, 351, and 501 (Wire code rules)

- CSA C22.2 No.56 (More safety rules)

- IP68 Rating (Keeps out water and dust)

This means they pass all tests. They are safe to use.

Why Connectors Need to be Good

Bad connectors can:

- Let in water

- Make sparks

- Break

- Make fires

- Hurt people

Good connectors like ours keep you safe.

Special Features

Our connectors have:

1. Quick-Install Parts

- Split sides to open fast

- Pre-made seals

- Easy to turn

- No tools needed

2. Wide Temperature Range

- Work in deep cold (-40°F)

- Work in high heat (221°F)

- Don’t crack when cold

- Don’t melt when hot

3. Anti-Spark Design

- Safe in gas areas

- Safe in dust areas

- No static build up

- Good grounding

Need to run many wires? Try our prensaestopas multiagujero for clean work.

Places That Use Our Connectors

Our connectors work in:

- Oil rigs

- Farms

- Mines

- Food plants

- Wet mills

- Ships

- Schools

- Homes

- Stores

- Grain bins

How to Pick the Right Connector

Ask these things:

- How big is your conduit?

- Will it get wet?

- Will it shake?

- Is it very hot or cold?

- Are there sparks or dust?

Then pick one that fits your needs.

Easy to Install

Our connectors are easy to put in:

- Cut your conduit

- Slip on the connector

- Tighten it

- Connect to box

- Done!

No hard steps. No long waits.

Parts That Work With Connectors

We also make:

- Junction box for wire joins

- Cable Gland Adaptors, Reducers & Enlargers to fit odd sizes

- Conduit tubes

- End caps

- Clamps

Save Money With Our Connectors

Our connectors save you money:

- Last a long time

- Don’t need to be fixed

- Easy to put in (saves work time)

- No leaks (saves wire costs)

- Bulk buy deals

Custom Orders

Need a special connector? We can make it!

- Odd sizes

- Weird angles

- Special metals

- New shapes

- Your name on it

Just tell us what you need.

Why Pick Our Company?

We are the best choice:

- 20 years making connectors

- All parts tested

- Fast shipping

- Help when you need it

- Fair prices

NEC and Safety Rules

The NEC rules say you must use good conduit parts. All our Conduit Connectors & Fittings meet these rules:

- NEC 350 (Flex Metal Conduit)

- NEC 351 (Liquid-Tight Flex Conduit)

- NEC 501 (Hot or Spark Areas)

- NEC 502 (Dust Areas)

- NEC 503 (Fiber Areas)

This means they are safe and legal to use.

Conduit Connector Chart

| Type | Best For | Keeps Out | Size Range |

|---|---|---|---|

| Liquid-Tight | Wet spots | Water, oil | 3/8″ – 4″ |

| Anti-Static | Gas areas | Sparks | 3/8″ – 1-1/4″ |

| High Heat | Hot places | Fire, heat | 3/8″ – 2″ |

| Cold Proof | Freezers | Ice, cold cracks | 3/8″ – 2″ |

| Direct Bury | In ground | Soil, rocks | 1/2″ – 4″ |

How to Order

It’s easy to get our conduit connectors:

- Pick your size

- Pick your type

- Tell us how many

- Tell us where to send them

- Pay

- Get them fast!

Help When You Need It

Need help? We are here:

- Phone help

- Email help

- Live chat

- How-to guides

- Size charts

Just ask!

Our Promise

We promise our conduit connectors will:

- Fit right

- Last long

- Keep safe

- Meet all rules

- Make you happy

If not, we fix it free.

Want to see all we make? Visit our main prensaestopas site for more great products!

Order Today: Keep your wires safe with our strong, safe, and easy-to-use conduit connectors!

Consulta

Especificación

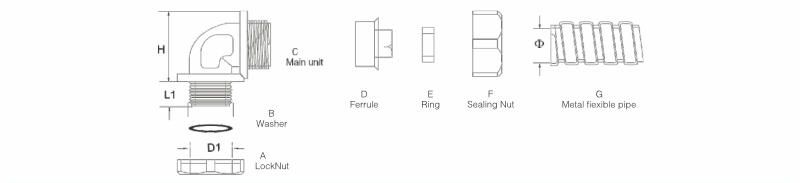

DWJ Series 90-Degree Corner Connector – Product Specification

| Category | Especificación |

|---|---|

| Product Name | DWJ Series 90-Degree Corner Connector |

| Thread Standard | Imperial System (G) |

| Material Composition | • Parts C & F: High-quality thickened zinc alloy (galvanized/plated) • Parts B & E: Nitrile rubber • Part D: Iron sheet |

| Product Color | Metallic (Silver White) |

| Operating Temperature | Continuous: -40°C to +100°C Short-term: Up to +120°C |

| Protection Rating | IP65 |

| Key Features | 1. Forms a precise 90-degree angle with the box after installation; thickened zinc alloy ensures an attractive appearance, tight structure, and high strength. 2. Customizable dimensions and thread standards available upon request beyond standard specifications. |

| Product Specifications | For detailed models and dimensions, refer to the separate specification table and size diagram. |

| Technical Parameter | |||||

| Suitable Metal flexible pipe | Thread standard | Thread O.D D1 | Thread Length L1 | Joint Length H | |

| Metric | G system | G system | |||

| 12(13) | 3/8″ | G3/8″ | 16.5 | 8 | 18 |

| 15(16) | 1/2″ | G1/2″ | 21.3 | 11 | 23 |

| 20(19) | 3/4″ | G3/4″ | 26.6 | 14 | 22 |

| 25 | 1″ | G1″ | 33.4 | 15 | 28 |

| 32 | 1-1/4″ | G1-1/4″ | 42.1 | 15 | 30 |

| 38(40) | 1-1/2″ | G1-1/2″ | 47.8 | 16 | 32 |

| 51(50) | 2″ | G2″ | 59.6 | 18 | 34 |

| 64(70) | 2-1/2″ | G2-1/2″ | 75.1 | 22 | 38 |

| 75(80) | 3″ | G3″ | 87.8 | 22 | 46 |

| 100 | 4″ | G4″ | 113 | 24 | 50 |

Preguntas frecuentes sobre prensaestopas

No hemos establecido un MOQ mínimo, personalizamos los productos según las necesidades del cliente. En teoría, podemos cumplir con los diferentes requisitos de MOQ de los clientes, pero diferentes MOQ tendrán diferentes costos.

Normalmente, nuestro tiempo de entrega es de 1 a 2 semanas para la producción por lotes. Para casos urgentes, podemos mejorarlo en 3~7 días.

Necesitamos la dimensión, el color, el hilo, el material, la certificación y más aplicaciones serán útiles.

Contamos con certificados CE, TUV y UL.

Ciertamente, podemos proporcionarle muestras estándar gratuitas según sus requisitos.