DKJ Metal Conduit Connectors

Keep your factory’s electrical wiring safe and secure with our rust-proof metal pipe fittings. Perfect for tough places like wind farms, mines, and construction sites. Made with zinc-coated steel that won’t rust or corrode – built to last:

- 15% longer lifespan compared to standard galvanized conduits

- Seamless compatibility with EMT, rigid, and flexible metal conduit systems

- NEC/IEC-certified designs for hazardous locations

- Customizable connectors and adapters for complex installations

Robust Metal Conduit Fittings for Harsh Industrial Environments

Industrial facilities demand conduit systems that withstand extreme temperatures, moisture, and chemical exposure. Our hot-dip zinc-coated steel conduit fittings combine a 85µm protective layer with precision threading to resist rust and abrasion. Ideal for:

- Oil & gas drilling sites: Survives saltwater sprays and hydrocarbon vapors

- Renewable energy farms: UV-stable performance for solar/wind installations

- Mining operations: Protects cables from rock debris and vibrations

Technical Specifications

| Material | Coating Thickness | Temperature Range | Certifications |

|---|---|---|---|

| ASTM A53 Steel | 85µm zinc | -40°F to 212°F | NEC 358, IEC 61386 |

“After switching to these conduit fittings, our offshore rigs saw a 60% reduction in electrical failures.” – Marine & Offshore Project Manager

For junction box integrations, explore our heavy-duty junction boxes with IP68 sealing.

Versatile Connector Solutions for Seamless Electrical Integration

From EMT compression couplings to flexible metal conduit connectors, our fittings ensure leak-proof cable and conduit networks. Key innovations:

- 360° Squeeze Design: Creates uniform pressure on conduits (1/2″ to 4″ sizes) without damaging wires

- Aluminum Alloy Bodies: 30% lighter than traditional metallic fittings for easier HVAC installations

- Dual-rated for outdoor/indoor use: NEMA 4X coating prevents water ingress

Installation Guide

- Cut conduit to length using a tubing cutter.

- Insert connector and hand-tighten until the thread grips.

- Apply 25 ft-lbs torque with a wrench for full compression.

Pair with Multi-Hole Cable Glands to organize complex wiring bundles.

Zinc-Coated Steel Conduits: Longevity Meets Performance

Unlike PVC or aluminum alternatives, our metal conduit fittings offer superior mechanical protection. Benefits include:

- EMT Compatibility: Integrates with existing electrical metallic tubing systems

- Fire Resistance: Withstands 1,800°F for 2 hours (UL 94 V-0 rated)

- EMI Shielding: Blocks interference in telecom and power facilities

Environmental Impact Analysis

- Recyclable Steel: 98% post-consumer scrap reuse rate

- Low VOC Coating: Meets EPA Electroplating Effluent Guidelines

For specialized applications, browse our Conduit Connectors & Fittings range.

Why Choose Us?

- 18-month warranty against corrosion

- CAD drawings and same-day shipping

- Custom pipe threading and coating services

Upgrade your infrastructure with conduits built for tomorrow’s challenges. Request a quote today!

Product Benefits Summary: Heavy-duty zinc-coated steel conduit fittings deliver corrosion-resistant, code-compliant electrical protection across industries—extending system lifespans while reducing maintenance costs.

Consulta

Especificación

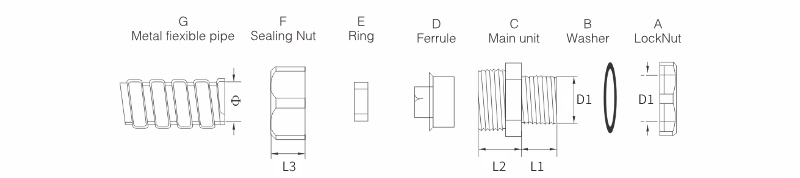

DKJ Series Card Sleeve Connector – Product Specification

| Category | Description |

|---|---|

| Product Name | DKJ Series Card Sleeve Connector |

| Material Composition | • Parts C & F: High-quality thickened zinc alloy (galvanized or plated). • Parts B & E: Nitrile Rubber. • Part D: Iron sheet. |

| Standard Color | Metallic Color (Silver White) |

| Operating Temperature | • Continuous: -40°C to +100°C • Short-term Peak: Up to +120°C |

| Protection Rating | IP65 |

| Key Features | 1. Durable & Aesthetic: Thickened zinc alloy construction offers a beautiful appearance, tight structure, and high strength. 2. Easy Installation: The hose sheath design ensures a tight connection, making assembly time-saving and convenient, with high tensile strength. 3. Excellent Resistance: Waterproof, dustproof, and resistant to salt, acid, alkali, alcohol, oil, grease, and general liquids. 4. Customizable: Sizes and thread standards can be modified upon request, in addition to standard specifications. |

| Product Specifications | For detailed models and dimensions, please refer to the separate specification table and size diagram. |

| Technical Parameters: Connector Compatibility & Dimensions | |||||||

| Suitable Metal fexible pipe | Thrade tio sted derex | Thin steel pipe | |||||

| Metric (mm) | Thread (G System) | Nominal Size | British Pipe Thread | Outer Diameter × Wall Thickness (mm) | Nominal Size | British Pipe Thread | Outer Diameter × Wall Thickness (mm) |

| φ10 | 5/16″ | #10 | 5/16″ | – | – | – | – |

| φ12 (13) | 3/8″ | #12 | 3/8″ | 17.00 × 2.25 | #15 | 5/8″ | 15.87 × 1.60 |

| φ15 (16) | 1/2″ | #15 | 1/2″ | 21.25 × 2.75 | #20 | 3/4″ | 19.05 × 1.80 |

| φ20 (19) | 3/4″ | #20 | 3/4″ | 26.75 × 2.75 | #25 | 1″ | 25.40 × 1.80 |

| φ25 | 1″ | #25 | 1″ | 33.50 × 3.25 | #32 | 1-1/4″ | 31.75 × 1.80 |

| φ32 | 1-1/4″ | #32 | 1-1/4″ | 42.25 × 3.25 | #40 | 1-1/2″ | 38.10 × 1.80 |

| φ38 (40) | 1-1/2″ | #40 | 1-1/2″ | 48.00 × 3.50 | #50 | 2″ | 50.80 × 2.00 |

| φ51 (50) | 2″ | #50 | 2″ | 60.00 × 3.50 | #70 | 2-1/2″ | 63.50 × 2.50 |

| φ64 (70) | 2-1/2″ | #70 | 2-1/2″ | 75.50 × 3.75 | #80 | 3″ | 76.20 × 3.20 |

| φ75 (80) | 3″ | #80 | 3″ | 88.50 × 4.00 | – | – | – |

| φ100 | 4″ | #100 | 4″ | 114.00 × 4.00 | – | – | – |

| φ125 | 5″ | #125 | 5″ | 140.00 × 4.50 | – | – | – |

| φ150 | 6″ | #150 | 6″ | 165.00 × 4.50 | – | – | – |

Preguntas frecuentes sobre prensaestopas

No hemos establecido un MOQ mínimo, personalizamos los productos según las necesidades del cliente. En teoría, podemos cumplir con los diferentes requisitos de MOQ de los clientes, pero diferentes MOQ tendrán diferentes costos.

Normalmente, nuestro tiempo de entrega es de 1 a 2 semanas para la producción por lotes. Para casos urgentes, podemos mejorarlo en 3~7 días.

Necesitamos la dimensión, el color, el hilo, el material, la certificación y más aplicaciones serán útiles.

Contamos con certificados CE, TUV y UL.

Ciertamente, podemos proporcionarle muestras estándar gratuitas según sus requisitos.