Anti-bending Cable Gland

What Is This?

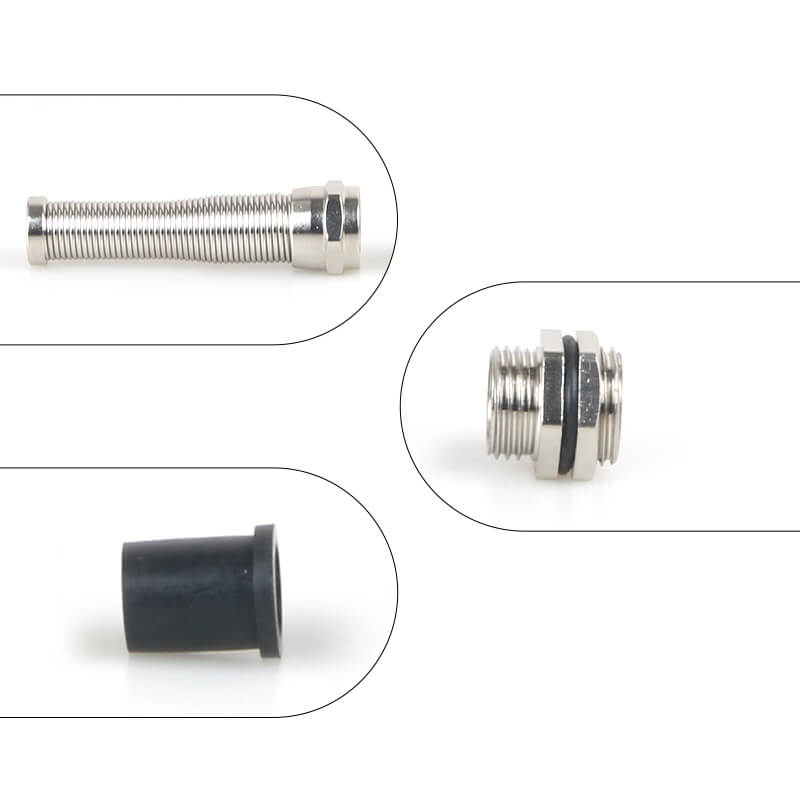

This is a cable gland that stops your cables from bending too much. It keeps cables safe when they move a lot or get pulled.

Why You Need It

- Stops breaks in your cables

- Keeps water out with IP68 seal

- Works in hot and cold places

- Fits many cable sizes

- Lasts a long time

Cool Things About Our Cable Gland

| Part | What It’s Made Of | What It Does |

|---|---|---|

| Body | Nylon or Brass | Stays strong, won’t rust |

| Spring | Stainless Steel | Stops cables from bending too much |

| Seal | Special rubber | Keeps water and dust out |

Where To Use It

Our metal water proof cable gland works great in:

- Wind farms where it’s very windy

- Underwater places that get wet

- Factories with moving machines

- Oil rigs where safety is big

- Cold rooms that freeze things

How It Protects

The spiral spring inside helps the cable bend a little bit, but not too much. This makes your cables last longer and work better.

Stays Strong In Tough Places

- Works in super hot (up to +120℃)

- Works in very cold (down to -40℃)

- Keeps out all water (IP68 rated)

- Safe for places that might go boom (ATEX certified)

Pick The Right Size

We have sizes for cables from very thin to very thick (up to 33mm). Not sure which to get? Check our size chart or ask us!

For bigger projects, try our multi hole cable gland when you need to fit many cables in one spot.

Two Main Types

1. Nylon Anti-Bending Glands

- Very light

- Won’t rust

- No bad smoke if there’s fire

- Great for clean rooms

2. Metal Anti-Bending Glands

- Super strong

- Best for tough jobs

- Works in very hot places

- Stops radio waves

Need a full system? Check our junction box options that work with these glands!

Easy To Put On

- Put your cable through the gland

- Tighten it with your hand

- That’s it! Your cable is now safe

Why People Buy From Us

- All our cable gland products pass tough tests

- We make them strong to last many years

- They work in very hot and very cold places

- Our glands keep out all water and dust

- They stop cables from getting hurt

Get Yours Today

Keep your cables safe from bends, pulls, and twists. Our anti-bending cable glands work in the toughest spots – wind farms, oil rigs, ships, and factories.

Order now to stop cable breaks before they start!

Inquiry

Specification

Product Specification

| Product Name | Anti bending brass cable glands |

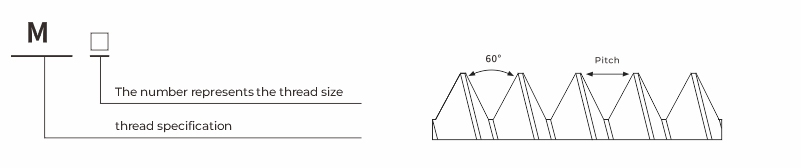

| Model | M, PG, NPT, G thread types |

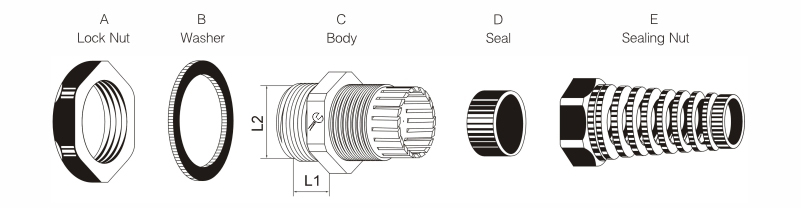

| Product Material | Nickel plated brass (body, tightening cap, nut); nitrile rubber (sealing ring, gasket) |

| Temperature range | Static -40 ℃ to 100 ℃, instantaneous heat resistance to 120 ℃; Dynamic -20 ℃ to 80 ℃, instantly heat-resistant to 100 ℃. |

| Product design features | Special clamping claw and rubber component design, with a wide range of cable clamping and strong tensile strength |

| Product performance | Waterproof, dustproof, salt resistant, acid and alkali resistant, alcohol, grease and general solvents. |

| Protection level | IP66 IP68 |

| Fire resistance | UL94 V-2 |

| UV resistant | F1 |

| Environmental protection | Compliant with RoHs standards, halogen-free |

| Certificate | CE, RoHS, REACH |

| Cable range | Refer to the specification table for specific size specifications and display diagram |

| Special function available | Extended, anti bending, single hole, multi hole, semi through, straight through |

| Application | Used in areas where a lot of cables and wires need to be inserted into housings with minimum space requirements |

| Machine and equipment manufacturing | |

| Photovoltaic | |

| Automation technology |

Technical Parameter

| Model | Cable Range (mm) | Thread O.D. L2 (mm) | Thread Length L1 (mm) | Spanner Size A & E (mm) |

|---|---|---|---|---|

| M12-R | 3-6.5 | 11.75 | 9.7 | 18/16 |

| M12-R | 2-5 | 11.75 | 9.7 | 18/16 |

| M16-R | 4-8 | 15.75 | 9.4 | 22/19 |

| M16-R | 2-6 | 15.75 | 9.4 | 22/19 |

| M18-R | 5-10 | 17.75 | 9.5 | 24/21 |

| M18-R | 3-7 | 17.75 | 9.5 | 24/21 |

| M20-R | 6-12 | 19.75 | 10 | 26/24 |

| M20-R | 5-9 | 19.75 | 10 | 26/24 |

| M22-R | 10-13 | 21.75 | 10 | 30/27 |

| M22-R | 7-12 | 21.75 | 10 | 30/27 |

| M25-R | 12-15 | 24.75 | 10 | 34/29 |

| M25-R | 10-12 | 24.75 | 10 | 34/29 |

| M27-R | 13-18 | 26.75 | 12.6 | 36/33 |

| M27-R | 9-16 | 26.75 | 12.6 | 36/33 |

Frequently Asked Questions About Cable Gland

We have not set a minimum MOQ, we customize products according to customer needs. In theory, we can meet different MOQ requirements of customers, but different MOQs will have different costs.

Normally our lead time is 1~2 weeks for batch production. For urgent case, we can improve it in 3~7 days.

We do need the dimention, colour, thread, material, certification, and more applications will be helpful.

We have CE, TUV and UL certificates.

Certainly, we can supply you the free standard samples according your requirement.