Nylon Conduit Connector SM-W

What Are Plastic Hose Barb Connectors?

Plastic hose barb connectors join tubes together. They have ridges that grip the inside of hoses. These parts help move water, air, and other things through tubes.

As a top Conduit Connectors maker, we make many types of connectors. Our Conduit Connectors & Fittings are strong and work well.

Why Pick Our Plastic Hose Barb Connectors?

- They last a long time

- They work in hot and cold places

- They keep fluids in and dirt out

- They are easy to put on tubes

What They’re Made Of

Our connectors come in many materials:

- Polyethylene: Tough and works in cold

- Polypropylene: Good with chemicals

- Nylon: Strong and hard

- Polyketone: Very tough

Each type works best for different jobs. Tell us what you need, and we’ll help you pick!

How Strong Are They?

Our plastic hose barb connectors can handle:

- Pressure: Up to 125 PSI (with clamps)

- Temperature: From -65°F to 190°F

- Certified: NSF 61 listed for clean water use

Types of Barb Designs

We make two main types:

- Single Barb: One ridge grips the tube

- Multi-Barb: Many ridges hold tighter

IL multi-ridge designs stop leaks better. Some have no seam line on the first barb to make an even better seal.

Sizes We Make

We make many sizes from small to big:

- 3/16 inch

- 1/4 inch

- 3/8 inch

- 1/2 inch

- 3/4 inch

- 1 inch

We can make what you need!

How to Use Them

Here’s how to use our connectors:

- Pick the right size for your tube

- Push the barbed end into the tube

- Use a clamp if you need it tighter

- Test to make sure it doesn’t leak

Places to Use Our Connectors

| Place to Use | Why It Works Well |

|---|---|

| House Plumbing | Keeps water in pipes |

| Factories | Moves air and fluids |

| Labs | Clean and safe for tests |

| Farms | Strong in sun and rain |

| Cars | Helps with fuel and cooling |

| Food Making | Safe for food contact |

More Products We Make

We don’t just make hose barb connectors. We also make:

- Plastic water proof cable gland for keeping wires safe

- Metal water proof cable gland for tough jobs

- Multi hole cable gland for many wires

- Junction box for wire connections

- Cable gland adaptors

- Reducers & enlargers

What Makes Our Connectors Special

Our connectors have special parts that make them work better:

- Ball-seat nipples with round ends for tight seals

- Y-connectors to split one tube into two

- Tees to make three-way connections

- Swivel fittings that turn for easy set-up

Jobs Our Connectors Do

Our plastic hose barb connectors help with:

- Moving water in houses

- Moving air in shops

- Moving chemicals in labs

- Moving fuel in cars

- Moving food liquids in food plants

Why They Save You Money

Our plastic connectors save money because:

- They last longer than cheap ones

- They don’t leak, so no waste

- They’re easy to put on, so less work time

- They don’t rust like metal ones

Custom Options

Need something special? We can help! We make custom parts just for you.

Our OEM/ODM service lets us make:

- Special sizes

- Special shapes

- Special materials

- Special colors

- Your brand name on parts

How to Order

Want to order our plastic hose barb connectors? It’s easy:

- Tell us what size you need

- Tell us what material you want

- Tell us how many you need

- We’ll make them for you

- We’ll ship them fast

Safe and Tested

All our parts are tested to make sure they work right. We check:

- How much pressure they can take

- How hot and cold they can get

- If they work with chemicals

- If they’re safe for food

Why Choose Us

Pick us for your plastic hose barb connectors because:

- We make high quality parts

- We have many types to pick from

- We offer custom options

- We give good prices

- We ship fast

- We help you find what you need

Our Other Connector Types

Besides plastic hose barb connectors, check out our Cable Gland Adaptors, Reducers & Enlargers for all your connection needs.

Get Help Picking the Right Connector

Not sure which connector you need? We can help! Our team knows all about:

- Hose barb sizes

- Material choices

- Pressure needs

- Temperature needs

- Chemical resistance

Just ask us, and we’ll help you find the right part.

Order Now

Ready to get your plastic hose barb connectors?

Contact us today to place an order or ask questions.

Telefono: +86 137 7301 8938 E-mail: [email protected] Sito web: www.cagland.com

Trust us for all your connector needs. We are the experts in plastic hose barb connectors, conduit connectors, and cable glands.

Visit our main site at CAGLAND to see our full range of products!

Inchiesta

Specifica

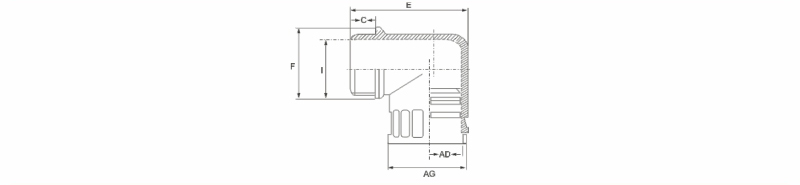

Product Specification

| Product Name | SM-W series hose straight joint |

| Product Material | Using PA nylon |

| Thread specifications | German system (PG)/metric system (M)/imperial system (G). |

| working temperature | -40°C~+110°C |

| Product color | Black (special colors can be customized). |

| Product Features | The internal lock buckle and special design of the body allow for easy insertion and removal without the need for tools |

| usage method | YDT-SM-W type hose connector is a hose matching product that can be connected to the equipment box, or can be connected to the electric equipment with internal thread inlet and outlet according to the selected thread. Simply insert the hose into the interface and lock it |

| Product specifications | Please refer to the specification and size diagram for specific models |

| Technical Parameters (Consolidated Table) | |||||||

| Modello | Suitable Pipe | Thread Spec | Outer Ø (mm) | I (mm) | C (mm) | E (mm) | F (mm) |

| PG Series | |||||||

| SM-W-PG7 | AD10.0 | PG7 | 12.5 | 9 | 10 | 32 | 16 |

| SM-W-PG9 | AD13.0 | PG9 | 15.2 | 11.6 | 10 | 34.5 | 20 |

| SM-W-PG11 | AD15.8 | PG11 | 18.6 | 13.5 | 10 | 37.5 | 24.3 |

| SM-W-PG13.5 | AD18.5 | PG13.5 | 20.4 | 16 | 11 | 43.5 | 27 |

| SM-W-PG16 | AD21.2 | PG16 | 22.5 | 17.5 | 13 | 49 | 31 |

| SM-W-PG21 | AD28.5 | PG21 | 28.3 | 23 | 13 | 57 | 34 |

| SM-W-PG29 | AD34.5 | PG29 | 37 | 30 | 14.5 | 64 | 43 |

| SM-W-PG36 | AD42.5 | PG36 | 47 | 38 | 14.5 | 72 | 50 |

| SM-W-PG48 | AD54.5 | PG48 | 59.3 | 52 | 16 | 84 | 64 |

| Metric Series | |||||||

| SM-W-M12 | AD10.0 | M12×1.5 | 12 | 9 | 10 | 32 | 16 |

| SM-W-M16 | AD13.0 | M16×1.5 | 16 | 11.6 | 10 | 34.5 | 20 |

| SM-W-M20 | AD21.2 | M20×1.5 | 20 | 15 | 13 | 49 | 31 |

| SM-W-M25 | AD28.5 | M25×1.5 | 25 | 19.5 | 13 | 57 | 34 |

| SM-W-M32 | AD34.5 | M32×1.5 | 32 | 27 | 14.5 | 64 | 43 |

| SM-W-M40 | AD42.5 | M40×1.5 | 40 | 35 | 14.5 | 72 | 50 |

| SM-W-M50 | AD54.5 | M50×1.5 | 50 | 44 | 16 | 84 | 64 |

| G-Series | |||||||

| SM-W-G1/2″ | AD21.2 | G1/2″ | 20.9 | 15 | 13 | 49 | 31 |

| SM-W-G3/4″ | AD28.5 | G3/4″ | 26.4 | 21 | 13 | 57 | 34 |

| SM-W-G1″ | AD34.5 | G1″ | 33 | 32 | 14.5 | 64 | 43 |

Domande frequenti sul pressacavo

Non abbiamo fissato un MOQ minimo, personalizziamo i prodotti in base alle esigenze del cliente. In teoria, possiamo soddisfare diversi requisiti MOQ dei clienti, ma diversi MOQ avranno costi diversi.

Normalmente il nostro tempo di consegna è di 1 ~ 2 settimane per la produzione in lotti. Per casi urgenti, possiamo migliorarlo in 3 ~ 7 giorni.

Abbiamo bisogno della dimensione, del colore, del filo, del materiale, della certificazione e altre applicazioni saranno utili.

Abbiamo certificati CE, TUV e UL.

Certamente, possiamo fornirti i campioni standard gratuiti in base alle tue esigenze.