Inhaltsübersicht

Wozu dient eine Kabelverschraubung? Drähte sicher und gut aufbewahren

Drähte, oder Kabel, sind überall. Sie bringen Strom zu unseren Lampen. Sie helfen Maschinen zu funktionieren. Sie verbinden Computer. Aber dort, wo diese Drähte in Kästen oder Maschinen führen, kann es Probleme geben.

1. Das große Problem: Unsichere Drähte

Drähte müssen in Dinge hineingehen. Denken Sie an eine große Maschine. Oder eine Außenlampe. Oder einen Stromkasten. Die Drähte müssen von außen nach innen geführt werden. Dieser Eintrittspunkt ist ein Schwachstelle.

Problem 1: Zeug dringt ein. Das für den Draht vorgesehene Loch kann böse Dinge eindringen lassen.

- Staub können sich einschleichen. Der Staub verstopft die Maschinen. Er kann dazu führen, dass elektrische Teile nicht mehr funktionieren.

- Wasser ist schlimmer! Regen oder Spritzer können ins Innere gelangen. Wasser und Strom sind sehr gefährlich zusammen. Wasser verursacht Rost. Es kann Kurzschlüsse verursachen. Maschinen gehen kaputt. Lichter gehen aus. Das zu reparieren kostet Geld und Zeit.

- Schmutz und Ungeziefer können ebenfalls einen Weg hinein finden. Sie können Schäden verursachen, die man nicht sofort sieht.

Problem 2: Drähte werden abgezogen. Drähte können versehentlich gezogen oder verdreht werden.

- Wenn ein Draht stark gezogen wird, kann er aus der Verbindung im Inneren herausreißen. Dadurch wird der Strom unterbrochen. Es kann das Kabel beschädigen. Es kann die Maschine beschädigen.

- Selbst kleine Wackler können mit der Zeit die Verbindungen lockern. Dies wird als Stamm. Zu viel Belastung ist schlecht für die Drähte.

Problem 3: Gefahr an besonderen Orten. An manchen Orten gibt es Gas oder Staub, die explodieren können.

- Denken Sie an Ölplattformen, Bergwerke oder Lackierereien. Ein winziger Funke aus Elektrizität kann eine große Explosion oder Feuer.

- Drähte, die an diesen Stellen in Dosen eingeführt werden, müssen besonders sicher. Die Eintrittsstelle muss den Austritt von Funken verhindern. Sie muss verhindern, dass Gas von außen eindringt.

Diese Probleme sind seriös. Kaputte Maschinen bedeuten Arbeitsausfall. Wasserschäden sind kostspielig. Lose Drähte sind unsicher. Explosionen sind schrecklich. Die Suche nach einer guten Methode zum Schutz dieser Eintrittsstellen für Kabel ist sehr wichtig. Sie brauchen etwas Starkes. Etwas Zuverlässiges. Etwas, das richtig passt. Aber was?

2. Die Lösung: Das ist die Kabelverschraubung!

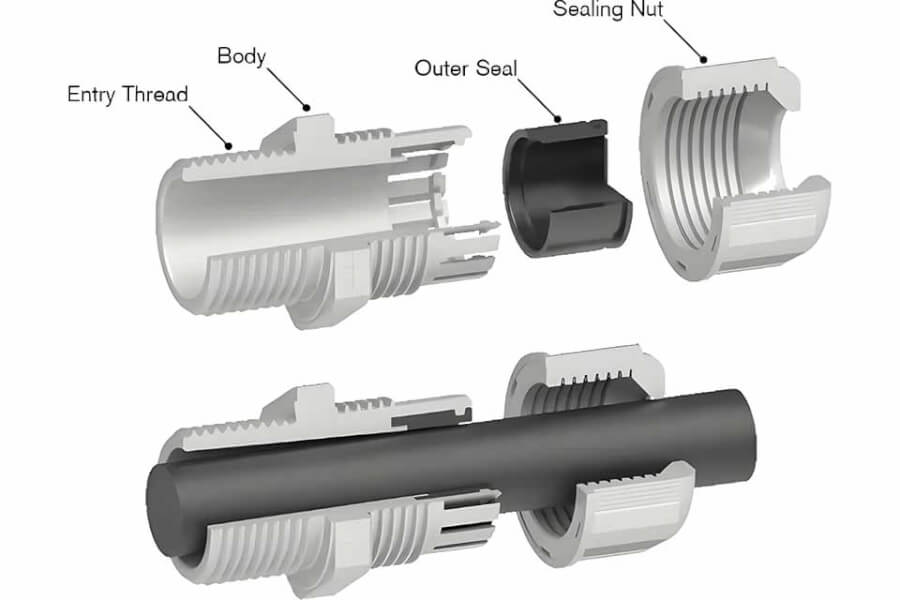

Glücklicherweise gibt es einen speziellen Helfer für diese Probleme. Er heißt Kabelverschraubung. Sie könnten auch Namen hören wie Kabelstecker oder Kabeleinführungsgerät.

Was ist eine Kabelverschraubung? Eine Kabelverschraubung ist ein kleines Teil, aber es leistet eine große Aufgabe. Es wird an der Öffnung angebracht, durch die ein Draht in eine Box oder Maschine geführt wird. Sie hält den Draht fest und dichtet die Öffnung ab. Stellen Sie sich das wie eine kleiner, starker Wächter für den Eintrittspunkt der Leitung.

Wir, als eine führender Hersteller von Kabelverschraubungen in Chinastellen diese wichtigen Teile her. Wir wissen, wie wichtig sie für die Sicherheit und das Funktionieren der Dinge sind. Wir stellen viele Typen her, um all diese kniffligen Probleme zu lösen.

3. Was bedeutet eine Kabelverschraubung Do? (Seine Superkräfte!)

Kabelverschraubungen haben mehrere wichtige Aufgaben oder Funktionen. Sie beheben die Probleme, über die wir gesprochen haben.

Festhalten des Kabels (Sicheres Festhalten):

- Problem: Drähte werden gezogen oder wackeln lose.

- Aufrühren: Ein loses Kabel kann die Stromversorgung unterbrechen, Schäden verursachen oder unsicher sein. Stellen Sie sich vor, das Kabel einer Überwachungskamera würde sich während eines Sturms lösen!

- Lösung: Die Kabelverschraubung Griffe den Draht fest. Wie starke Finger, die ihn festhalten. Es verhindert, dass der Draht herausgezogen wird, auch wenn es Vibrationen oder Zerrungen gibt. So bleibt die Verbindung im Inneren sicher.

Das Eindringen von Schadstoffen verhindern (Environmental Sealing):

- Problem: Staub, Schmutz, Wasser und Ungeziefer gelangen durch die Drahtöffnung in den Kasten.

- Aufrühren: Wasser in Schaltkästen ist ein Rezept für eine Katastrophe - Stromschläge, Kurzschlüsse, Rost, Ausfälle! Staub macht die Arbeit zunichte. Dies zu beheben, kostet Zeit und Geld, das Sie nicht haben.

- Lösung: Kabelverschraubungen haben Dichtungen, die oft aus Gummi oder speziellem Kunststoff bestehen. Diese Dichtungen drücken fest gegen den Draht und das Loch in der Dose. Dies schafft eine Barriere. Es hält Staub ab. Es hält Wasser ab, selbst bei starkem Strahlwasser oder unter Wasser (je nach Typ!). Dieses Schutzniveau wird gemessen durch einen IP-Einstufung. Eine höhere IP-Einstufung bedeutet besseren Schutz. Unser wasserdichte Kabelverschraubungen aus Metall und wasserdichte Kabelverschraubungen aus Kunststoff sind großartige Beispiele, die für höchste Dichtungsleistung ausgelegt sind.

Entlastung (Strain Relief):

- Problem: Zug- oder Biegekräfte auf das Kabel beschädigen die Verbindungen im Inneren.

- Aufrühren: Ständige kleine Züge oder scharfe Biegungen schwächen die winzigen Drähte im Inneren des Kabels. Schließlich brechen sie, und das Gerät fällt aus. Den Bruch zu finden, kann frustrierend sein!

- Lösung: Die Kabelverschraubung nimmt diese Belastung auf vor es erreicht die empfindlichen Verbindungen. Es fängt die Zug- und Biegekräfte ab. Das schützt das empfindliche Innenleben und sorgt für eine längere Lebensdauer der gesamten Anlage.

Sicherheit an gefährlichen Orten (Gefahrenprävention):

- Problem: An Orten mit brennbaren Gasen oder Stäuben besteht die Gefahr, dass Funken Explosionen oder Brände verursachen.

- Aufrühren: Eine Explosion kann immense Schäden, Verletzungen oder sogar den Tod verursachen. Standardteile sind in diesen Fällen nicht sicher genug Gefahrenbereiche. Die Folgen eines Scheiterns sind zu hoch.

- Lösung: Spezial explosionsgeschützte Kabelverschraubungen verwendet werden. Diese werden gebaut extra stark. Sie sind so konstruiert, dass sie jeden Funken im Inneren der Box eindämmen. Sie verhindern auch, dass brennbares Gas in die über der Drüse. Diese benötigen oft spezielle Zertifikate (wie ATEX oder IECEx), um zu beweisen, dass sie für diese schwierigen Aufgaben sicher sind. Die Verwendung der richtigen ATEX-zertifizierte Kabelverschraubungen ist nicht nur klug, sondern in diesen Bereichen oft auch gesetzlich vorgeschrieben.

Ordnung in den Kabeln (Kabelmanagement):

- Problem: Viele Kabel in einer Schalttafel können unordentlich aussehen und schwer zu handhaben sein.

- Aufrühren: Ein Wirrwarr von Kabeln macht es schwer, Dinge zu reparieren oder neue Verbindungen herzustellen. Es sieht unprofessionell aus und kann sogar eine Stolperfalle sein.

- Lösung: Kabelverschraubungen helfen bei der Organisation des Kabeleingangs in einer Schalttafel. Sie bieten saubere, sichere Eintrittspunkte. Für Situationen, in denen viele Drähte an einer Stelle eingeführt werden müssen, sind unsere Mehrloch-Kabelverschraubungen sind eine perfekte Lösung, die für Ordnung und Dichtheit sorgt.

Als Hersteller konzentrieren wir uns auf die Herstellung von Kabelverschraubungen, die alle diese Aufgaben hervorragend erfüllen. Hochwertige Materialien und sorgfältige Konstruktion bedeuten bessere Sicherheit und längere Lebensdauer für Ihre Ausrüstung.

4. Wo werden Kabelverschraubungen eingesetzt? (Beispiele aus der Praxis)

Kabelverschraubungen werden verwendet in so viele Orteoft im Verborgenen, aber sie leisten wichtige Arbeit. Hier sind einige gängige Beispiele:

Fabriken und Werkstätten:

- Problem: Maschinen brauchen Strom und Steuersignale. Überall verlaufen Drähte. Oft gibt es Staub, Öl- oder Wasserspritzer.

- Aufrühren: Ungeschützte Drähte können zu Maschinenausfällen führen, die die Produktion stoppen und Geld kosten. Sicherheit ist auch im Bereich beweglicher Teile wichtig.

- Lösung: Industrielle Kabelverschraubungen werden an Schalttafeln, Motoren und Geräten verwendet. Sie schützen die Verbindungen vor den Umgebungsbedingungen in der Fabrik und verhindern, dass sich die Drähte durch Vibrationen lösen. Kabelverschraubungen aus Messing sind hier beliebt, weil sie robust und korrosionsbeständig sind.

Außenbeleuchtung und Beschilderung:

- Problem: Beleuchtungen an Gebäuden, Straßen oder Schildern sind Regen, Schnee, Sonne und Wind ausgesetzt.

- Aufrühren: Das Eindringen von Wasser in elektrische Teile im Freien ist eine der Hauptursachen für Ausfälle. Durchgebrannte Lampen zu ersetzen oder Kurzschlüsse zu reparieren ist mühsam, vor allem wenn sie hoch oben liegen!

- Lösung: Wasserdichte Kabelverschraubungen sind unerlässlich. Sie verfügen über hohe IP-Schutzarten (wie IP67 oder IP68), um eine dichte Abdichtung gegen Witterungseinflüsse zu gewährleisten. Unser wasserdichte Kabelverbindersowohl aus Metall als auch aus Kunststoff, sind ideal für diese Arbeiten im Freien.

Kraftwerke und Stromnetze:

- Problem: Es werden riesige Mengen an Energie verwaltet. Zuverlässigkeit ist entscheidend. Viele Verbindungen befinden sich im Freien oder unter schwierigen Bedingungen.

- Aufrühren: Ein Ausfall des Stromnetzes kann Tausende von Menschen betreffen. Die Anlagen müssen jahrzehntelang den Witterungsbedingungen und hohen elektrischen Belastungen standhalten.

- Lösung: Hochbelastbare Kabelverschraubungen, oft hergestellt aus Metall (wie Messing oder Edelstahl), verwendet werden. Sie bieten eine starke Zugentlastung und Schutz vor Umwelteinflüssen für kritische Stromkabel.

Telekommunikationsboxen und Datenzentren:

- Problem: Empfindliche Glasfaser- und Datenkabel müssen beim Eintritt in Schränke oder Gebäude geschützt werden. Staub und Feuchtigkeit können die Signale stören.

- Aufrühren: Ein verschmutzter oder nasser Anschluss kann die Internetgeschwindigkeit verlangsamen oder zu einem kompletten Ausfall führen. Es ist wichtig, empfindliche Geräte sauber zu halten.

- Lösung: Kabelverschraubungen sorgen für saubere, sichere Einführungsstellen. Kunststoff-Kabelverschraubungen werden hier häufig verwendet, da sie leicht und chemikalienbeständig sind und eine kostengünstige Abdichtung bieten.

Schiffe und Boote (Marine):

- Problem: Ständiger Kontakt mit Salzwasser, Feuchtigkeit und Vibration.

- Aufrühren: Salzwasser ist sehr korrosiv. Ein Ausfall der Ausrüstung auf See kann gefährlich sein. Alles muss besonders robust und wasserdicht sein.

- Lösung: Wasserdichte Kabelverschraubungen aus korrosionsbeständigen Materialien wie Edelstahl oder spezielles Messing in Marinequalität verwendet werden. Hohe IP-Schutzarten (IP68) sind Standard.

Ölplattformen, Raffinerien, Bergwerke (Gefahrenbereiche):

- Problem: Entflammbare Gase oder Stäube stellen eine Explosionsgefahr dar.

- Aufrühren: Die Sicherheit hat oberste Priorität. Jedes elektrische Bauteil muss so konstruiert sein, dass es sich nicht entzünden kann. Standardteile sind verboten.

- Lösung: Nur explosionsgeschützte Kabelverschraubungen (ATEX/IECEx-zertifiziert) sind zulässig. Diese Spezialverschraubungen sind so konzipiert und getestet, dass sie Explosionen eindämmen und das Entweichen von Flammen verhindern. Die Wahl der richtigen explosionsgeschützte Kabelverschraubung ist entscheidend.

Medizinische Ausrüstung:

- Problem: Die Geräte müssen zuverlässig sein und häufig gereinigt oder sterilisiert werden. Die Verbindungen müssen sicher sein.

- Aufrühren: Versagen ist in medizinischen Einrichtungen keine Option. Die Ausrüstung muss leicht zu warten und hygienisch sein.

- Lösung: Hochwertige Kabelverschraubungen, teilweise aus rostfreiem Stahl zur einfachen Reinigung, sorgen für zuverlässige Verbindungen und verhindern das Eindringen von Verunreinigungen.

Grundsätzlich gilt, dass überall dort, wo ein Kabel sicher in ein Gehäuse eingeführt werden muss, ein Kabelverschraubung ist wahrscheinlich notwendig!

5. Verschiedene Arten von Kabelverschraubungen: Die Wahl des richtigen Werkzeugs

Nicht alle Kabelverschraubungen sind gleich. Es gibt sie in verschiedenen Arten, Materialien und Größen, die für unterschiedliche Aufgaben gemacht sind. Die Wahl der richtigen Verschraubung ist wichtig.

Typen basierend auf ihren Aufgaben:

- Standard-Industrieverschraubungen: Gut für den allgemeinen Gebrauch. Sie bieten eine gute Abdichtung und Zugentlastung für viele gängige Situationen.

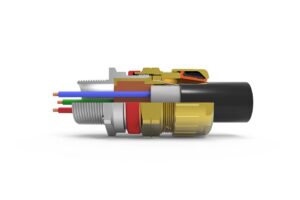

- Gepanzerte Kabelverschraubungen: Wird für Kabel verwendet, die eine Metallarmierung (wie Steel Wire Armour - SWA) für zusätzlichen Schutz haben. Diese Verschraubungen erfüllen zwei Aufgaben: Sie dichten den äußeren Teil des Kabels ab UND sie stellen eine elektrische Verbindung mit der Metallarmierung her. Diese Erdung ist wichtig für die Sicherheit. Es gibt verschiedene Typen für unterschiedliche Panzerungen.

- Nicht gepanzerte Kabelverschraubungen: Verwendet für Kabel ohne Metallarmierung, wie bei Standard-Kunststoff- oder Gummimantelkabeln. Sie konzentrieren sich auf die Abdichtung und Zugentlastung des Kabels selbst.

- Einfachkompression vs. Doppelkompressionsverschraubungen: Diese Begriffe beziehen sich oft auf gepanzerte Kabelverschraubungen.

- Einfache Verdichtung: Dichtet den Außenmantel des Kabels ab. Wird oft in trockenen Innenräumen verwendet.

- Doppelte Komprimierung: Dichtet sowohl den Außenmantel als auch den inneren Teil des Kabels unter der Panzerung ab. Bietet zusätzliche Abdichtung und Schutz, gut für härtere Bedingungen.

- Explosionsgeschützte Verschraubungen: Speziell für explosionsgefährdete Bereiche entwickelt und zertifiziert (ATEX/IECEx). Sie verhindern Explosionen. Sie sehen anders aus und sind viel stabiler gebaut.

- Wasserdichte Verschraubungen: Entworfen mit hohen IP-Schutzklassen (wie IP67, IP68), um Wasser fernzuhalten, sogar unter Wasser. Unverzichtbar für den Einsatz im Freien oder an feuchten Orten. Wir sind spezialisiert auf wasserdichte Kabelverschraubungen aus Metall und wasserdichte Kabelverschraubungen aus Kunststoff.

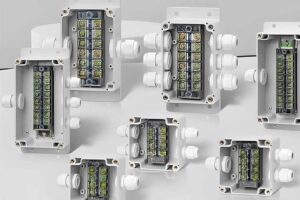

- Multi-Loch-Verschraubungen: Mit diesen cleveren Verschraubungen können mehrere Kabel durch eine Verschraubung und ein Loch in der Dose geführt werden [^Multi-hole-internal]. Das spart Platz und reduziert die Anzahl der benötigten Löcher. Unser Mehrloch-Kabelverschraubungen bieten eine großartige platzsparende Lösung.

Typen auf Basis von Material:

Das Material, aus dem eine Kabelverschraubung besteht, hat Einfluss darauf, wie stark sie ist, wo sie eingesetzt werden kann und wie viel sie kostet.

Kabelverschraubungen aus Messing:

- Profis: Sehr widerstandsfähig, korrosionsbeständig (vor allem, wenn vernickelt), gut geeignet für industrielle Anwendungen.

- Nachteile: Kann teurer sein als Kunststoff.

- Beste Verwendung: Fabriken, Stromversorgungssysteme, allgemeine Industriearbeiten. Häufig verwendet für Panzerkabelverschraubungen.

Kabelverschraubungen aus Edelstahl:

- Profis: Ausgezeichnete Korrosionsbeständigkeit (am besten für Salzwasser oder Chemikalien), sehr robust, leicht zu reinigen.

- Nachteile: In der Regel die teuerste Option.

- Beste Verwendung: Meeresumgebungen, Lebensmittelverarbeitung, Chemieanlagen, medizinische Geräte.

Kunststoff (Nylon/Polyamid) Kabelverschraubungen:

- Profis: Leicht, beständig gegen viele Chemikalien, kostengünstig, gute Isolatoren (leiten den Strom nicht).

- Nachteile: Mechanisch nicht so stabil wie Metall, kann im Laufe der Zeit durch starkes Sonnenlicht (UV) beeinträchtigt werden, wenn es nicht speziell behandelt wird.

- Beste Verwendung: Allgemeine Anwendungen, Schaltkästen, Elektronik, Innenanwendungen, Situationen, in denen Kosten eine Rolle spielen. Unser wasserdichte Kabelverschraubungen aus Kunststoff bieten eine zuverlässige Abdichtung zu einem guten Preis.

Aluminium-Kabelverschraubungen:

- Profis: Leichter als Messing oder Stahl, gute Leitfähigkeit.

- Nachteile: Nicht so stabil und korrosionsbeständig wie Edelstahl.

- Beste Verwendung: Spezielle Anwendungen, bei denen das Gewicht eine Rolle spielt.

Als Hersteller mit Sitz in Chinabieten wir eine breite Palette dieser Materialien an, darunter hochwertige Metall (Messing und rostfreier Stahl) und langlebig Kunststoff Wir bieten Ihnen eine Vielzahl von Optionen, damit Sie die perfekte Lösung für Ihre Bedürfnisse und Ihr Budget finden können. Wir produzieren auch Abzweigdosendie oft mit Kabelverschraubungen zusammenarbeiten, um elektrische Verbindungen zu schützen.

6. Der wachsende Bedarf an Kabelverschraubungen: Einblicke in den Markt

Die Welt braucht mehr Kabelverschraubungen! Der Markt für diese kleinen, aber wichtigen Teile wächst.

| Kategorie | Wichtige Daten/Einblicke | Quelle(n) |

|---|---|---|

| Marktgröße (2025) | Geschätzt etwa 2,0 Mrd. USD | |

| Wachstumsrate | Wachsen über 5-6% pro Jahr (CAGR) | |

| Projizierte Größe | Voraussichtlich werden fast 3 Milliarden USD bis 2030-2033 | |

| Haupttreiber | - Notwendigkeit der Sicherheit in gefährlichen Bereichen (Öl/Gas, Bergbau) - Wachstum bei den erneuerbaren Energien (Sonne, Wind) - Mehr Automatisierung in Fabriken - Ausbau der Telekommunikationsnetze (wie 5G) | |

| Beliebte Materialien | – Metall (Messing/Stahl): Starke Verwendung in der Industrie (etwa 65% auf einigen Märkten) – Kunststoff (Nylon): Weit verbreitetes Kosten-Nutzen-Verhältnis (etwa 40%) | |

| Wichtige Merkmale | – Wasserabdichtung (hohe IP-Schutzarten) für den Einsatz im Freien/Nassbereich erforderlich – Explosionsgeschützt (ATEX/IECEx) unerlässlich für gefährliche Zonen | |

| Herstellung | Es gibt viele Hersteller auf der ganzen Welt, darunter auch spezialisierte Produzenten in Regionen wie China. |

Was bedeutet das? Mehr Gebäude, mehr Maschinen, mehr grüne Energie und mehr Verbindungen bedeuten mehr Kabel. Und mehr Kabel bedeuten mehr Bedarf an sichere, zuverlässige Kabelverschraubungen.

- Problem: Mit immer komplexeren Systemen und strengeren Vorschriften (vor allem in Bezug auf Sicherheit und Umwelt) muss die rechtsist eine hochwertige Kabelverschraubung wichtiger denn je.

- Aufrühren: Die Verwendung einer falschen oder minderwertigen Verschraubung kann zu Ausfällen, Sicherheitsrisiken und zur Nichteinhaltung von Normen führen. Dies kann Projekte stoppen oder später große Probleme verursachen.

- Lösung: Die Zusammenarbeit mit einem erfahrenen Kabelverschraubungshersteller wie uns in China haben Sie Zugang zu einer breiten Palette zertifizierter, zuverlässiger Produkte. Wir verstehen die wachsende Nachfrage nach wasserdichte Kabelverbinder, explosionsgeschützt Typen und effiziente Lösungen wie Mehrloch-Kabelverschraubungen. Wir bieten die Qualität, die für die anspruchsvollen Anwendungen von heute erforderlich ist.

7. Wie wählt man die Rechts Kabelverschraubung: Eine einfache Checkliste

Die Wahl der richtigen Kabelverschraubung gewährleistet Sicherheit und eine lange Lebensdauer. Hier ist, was Sie beachten sollten:

Welche Art von KABEL verwenden Sie?

- Ist es gepanzert (wie SWA)? Sie brauchen eine Panzerkabelverschraubung.

- Ist es nicht gepanzert (Standard-Kunststoff/Gummi)? Verwenden Sie eine nicht gepanzerte Stopfbuchse.

- Wie groß ist das Kabel? Messen Sie die Durchmesser (Breite) sorgfältig ab. Die Verschraubung muss eng am Kabel anliegen. Verschraubungen gibt es in vielen Größen. Prüfen Sie den Größenbereich für die Verschraubung.

Wie sieht die UMGEBUNG am Einsatzort aus?

- Drinnen und trocken? Eine Standard-Kunststoff- oder Messingverschraubung könnte ausreichen.

- Im Freien, nass oder staubig? Sie BRAUCHEN eine wasserdichte Kabelverschraubung mit einer guten IP-Einstufung (wie IP67 oder IP68). Berücksichtigen Sie die UV-Beständigkeit für sonnige Standorte. Unser wasserdichte Kabelverschraubungen aus Metall und wasserdichte Kabelverschraubungen aus Kunststoff sind für diesen Zweck gebaut.

- Gefährlicher Bereich (Gas-/Staubrisiko)? Sie MÜSSEN einen zertifizierten explosionsgeschützte Kabelverschraubung (ATEX/IECEx). Keine Ausnahmen!

- Ätzende Chemikalien oder Salzwasser? Wählen Sie Edelstahl oder hochwertiges vernickeltes Messing.

Welches MATERIAL sollte die Drüse haben?

- Bedarf Stärke und Langlebigkeit für die Industrie? Messing ist eine solide Wahl.

- Sie brauchen die beste Korrosionsbeständigkeit? Rostfreier Stahl ist Spitzenklasse.

- Sie brauchen eine Kostengünstigeine leichte Option für den allgemeinen Gebrauch? Kunststoff (Nylon) funktioniert gut.

Wie groß ist die LÜCKE in der Box/Platte?

- Die Drüse hat eine Gewinde (wie eine Schraube), die in das Loch passt. Die Gewindegröße (z. B. M20, PG16, NPT 1/2″) muss zur Bohrung passen. Möglicherweise benötigen Sie auch eine Gegenmutter auf der Innenseite.

Benötigen Sie spezielle BESCHEINIGUNGEN?

- Für explosionsgefährdete Bereiche, ATEX oder IECEx ist obligatorisch.

- Für einige Märkte (wie Nordamerika), UL oder CSA Auflistung erforderlich sein könnte.

- IP-Einstufung zeigt, wie wasserdicht/staubdicht es ist.

Problem: Die Auswahl scheint kompliziert zu sein! So viele Möglichkeiten. Aufrühren: Die Wahl der falschen Stopfbuchse führt zu Undichtigkeiten, losen Drähten, Sicherheitsmängeln oder dazu, dass die Arbeit neu gemacht werden muss. Das ist frustrierend und kostspielig. Lösung: Raten Sie nicht! Prüfen Sie die Kabelspezifikationen, machen Sie sich mit der Umgebung vertraut, und achten Sie auf die richtigen Zertifizierungen. Als erfahrene Hersteller können wir Sie dabei unterstützen. Unser Produktsortiment umfasst wasserdichte Kabelverschraubungen aus Metall, wasserdichte Kabelverschraubungen aus Kunststoff, Mehrloch-Kabelverschraubungenund Zubehör wie AbzweigdosenSie sind für verschiedene Bedürfnisse konzipiert und klar spezifiziert, um Ihnen die richtige Wahl zu erleichtern.

8. Installation von Kabelverschraubungen: Richtiges Vorgehen

Selbst die beste Kabelverschraubung funktioniert nicht gut, wenn sie nicht richtig installiert ist.

Einfache Schritte:

- Vorbereiten des Kabels: Die äußere Schicht des Kabels, falls erforderlich, gemäß den Anweisungen der Verschraubung vorsichtig abisolieren. Die inneren Drähte dürfen nicht eingekerbt werden!

- Zerlegen Sie die Drüse: Schrauben Sie die Teile der Stopfbuchse ab (in der Regel eine Überwurfmutter, eine Dichtung und ein Gehäuse).

- Teile auf das Kabel schieben: Schieben Sie zuerst die Überwurfmutter und dann die Dichtung in der richtigen Reihenfolge auf das Kabel.

- Einsatz Stopfbuchsgehäuse: Schrauben Sie den Hauptteil der Stopfbuchse in das Loch in der Dose oder Platte. Ziehen Sie die Verschraubung mit einem Schraubenschlüssel an, oft mit einer Gegenmutter auf der Innenseite zur Sicherung.

- Kabel einlegen: Schieben Sie das Kabel durch den Verschraubungskörper in die Dose.

- Dichtung anziehen: Schieben Sie die Dichtung in den Stopfbuchsenkörper.

- Ziehen Sie die Hutmutter fest.: Schrauben Sie die Überwurfmutter auf den Verschraubungskörper. Beim Anziehen drückt sie die Dichtung fest gegen das Kabel, wodurch die wasser- und staubdichte Barriere entsteht und das Kabel geklemmt wird [^8]. Ziehen Sie sie fest an, aber überdrehen Sie sie nicht und beschädigen Sie das Kabel oder die Verschraubung nicht.

- Siehe: Ziehen Sie leicht am Kabel, um sicherzustellen, dass es sicher gehalten wird. Prüfen Sie, ob die Dichtung gleichmäßig zusammengedrückt aussieht.

Tipps für den Erfolg:

- Verwenden Sie die richtige Stopfbuchsengröße! Zu groß = dichtet nicht ab. Zu klein = passt nicht oder beschädigt das Kabel.

- Verwenden Sie die richtigen Werkzeuge: Schlüssel oder Schraubenschlüssel der richtigen Größe verhindern Schäden.

- Dinge sauber halten: Schmutz auf dem Gewinde oder der Dichtung kann eine gute Abdichtung verhindern.

- Anweisungen befolgen: Insbesondere bei gepanzerten oder explosionsgeschützten Stopfbuchsen sind die spezifischen Schritte sorgfältig zu beachten.

- Regelmäßige Kontrollen: In schwierigen Umgebungen sollten Sie die Stopfbuchsen regelmäßig überprüfen, um sicherzustellen, dass sie noch dicht sind und die Dichtungen gut aussehen.

Problem: Installationsfehler kommen vor. Aufrühren: Eine schlecht installierte Stopfbuchse kann undicht werden, sich lösen oder ihre Sicherheitsfunktion nicht erfüllen, wodurch der ganze Zweck der Verwendung zunichte gemacht wird! Dies kann zu Geräteschäden oder gefährlichen Situationen führen. Lösung: Nehmen Sie sich Zeit, verwenden Sie die richtigen Teile, und befolgen Sie die Anweisungen. Hochwertige Verschraubungen, wie die von uns hergestellten, sind oft für eine einfachere und zuverlässigere Installation ausgelegt. Klare Anweisungen und einheitliche Größenangaben helfen den Installateuren, es gleich beim ersten Mal richtig zu machen.

9. Häufig gestellte Fragen (FAQs)

F: Kann ich jede Kabelverschraubung im Freien verwenden?

- A: Nein. Sie benötigen eine wasserdichte Kabelverschraubung speziell für die Verwendung im Freien entwickelt, mit einer hohen IP-Schutzart wie IP67 oder IP68 [^8]. Standardverschraubungen für den Innenbereich sind undicht. Suchen Sie nach unseren wasserdichte Kabelverschraubungen aus Metall oder wasserdichte Kabelverschraubungen aus Kunststoff.

F: Brauche ich wirklich spezielle Verschraubungen für explosionsgefährdete Bereiche?

- A: Ja, absolut! Das ist eine strenge Sicherheitsanforderung. Sie müssen explosionsgeschützte (ATEX/IECEx-zertifizierte) Kabelverschraubungen in Bereichen mit brennbarem Gas oder Staub. Alles andere ist extrem gefährlich und wahrscheinlich illegal.

F: Was ist der Hauptunterschied zwischen einer Messing- und einer Kunststoff-Kabelverschraubung?

- A: Messing ist stärker und besser für harte Industriearbeiten geeignet. Kunststoff (Nylon) ist leichter, oft billiger und eignet sich für den allgemeinen Gebrauch oder den Einsatz von Chemikalien. Die Wahl hängt von den Anforderungen an die Stärke, die Umwelt und das Budget ab.

F: Was bedeutet die IP-Einstufung?

- A: IP steht für Ingress Protection. Sie hat zwei Zahlen (z. B. IP68). Die erste Zahl steht für den Schutz gegen Feststoffe (wie Staub, 6 ist die höchste Zahl). Die zweite Zahl bewertet den Schutz gegen Flüssigkeiten (wie Wasser, 7 bedeutet Eintauchen bis zu 1 m, 8 bedeutet tieferes/längeres Eintauchen). Höhere Zahlen bedeuten einen besseren Schutz.

F: Kann eine Verschraubung mehrere Kabel aufnehmen?

- A: Ja! Mehrloch-Kabelverschraubungen sind dafür konzipiert [^multi-hole-internal]. Sie haben mehrere Löcher in der Dichtung, um mehrere Kabel sicher durch einen Einführungspunkt zu führen. Sehen Sie sich unser Mehrloch-Kabelverschraubungen für diese Anwendungen.

10. Schlussfolgerung: Der unbesungene Held der elektrischen Sicherheit

Kabelverschraubungen sind zwar klein, aber ihre Aufgabe ist riesig.

- Problem Rekapitulation: Ungeschützte Kabeleinführungen lassen schädlichen Staub und Wasser eindringen, ermöglichen es, dass sich Kabel lösen und zu Ausfällen führen, und können an gefährlichen Orten extrem gefährlich sein.

- Erregung Rekapitulation: Diese Probleme führen zu kostspieligen Ausfallzeiten, frustrierenden Reparaturen, unsicheren Bedingungen und potenziell katastrophalen Unfällen wie Bränden oder Explosionen. Die Suche nach einer zuverlässigen Lösung ist entscheidend.

- Lösung Rekapitulation: Kabelverschraubungen sind die Antwort! Sie sicher Kabel, Siegel der Umwelt, bieten Zugentlastungund gewährleisten Sicherheitinsbesondere bei spezialisierten Typen wie wasserdicht und explosionsgeschützt Stopfbuchsen. Die Wahl des richtigen Typs und Materials sowie der korrekte Einbau sind entscheidend.

Als engagierter Hersteller von Kabelverschraubungen in ChinaWir kennen diese Herausforderungen sehr genau. Wir sind bestrebt, hochwertige und zuverlässige Lösungen anzubieten - von robusten wasserdichte Kabelverschraubungen aus Metall für den harten industriellen Einsatz geeignet, bis hin zu kostengünstigen wasserdichte Kabelverschraubungen aus Kunststoff für allgemeine Anwendungen, und innovative Mehrloch-Kabelverschraubungen für platzsparende Bedürfnisse. Wir liefern auch wichtiges Zubehör wie Abzweigdosen.

Wenn Sie sich für hochwertige Kabelverschraubungen entscheiden, schützen Sie Ihre Geräte, gewährleisten einen zuverlässigen Betrieb und halten Sicherheitsstandards ein. Sie sind die leisen, starken Wächter, die unsere elektrische Welt verbunden und sicher halten.