Table of Contents

Can a Cable Go Through a Gland? Yes! Here’s Why You Need Them!

Do you have wires or cables? Do they need to go into a box or a wall?

You might worry. Is it safe? Will water get in? Will dust make things dirty? Will the cable pull out?

(Problem) Yes, cables are important. But they can be weak. They carry power or signals. But things like water, dust, pulling, and even sparks can hurt them. If a cable gets hurt, things stop working. Lights might go out. Machines might break. It can even be dangerous!

(Agitate) Think about rain getting into an outdoor box. Zap! The power goes out. Or think about dust in a factory. It gets into tiny spaces. It can make machines stop. What if a cable is pulled too hard? It might break inside. No more signal! This costs money to fix. It takes time. Sometimes, in special places like oil rigs or mines, a tiny spark can cause a big boom! This is very, very scary. Finding the right part to stop these problems can feel hard.

(Solution) But wait! There is a super helper for cables. It’s called a cable gland. And yes, a cable can go through a cable gland! That’s exactly what they are for!

A cable gland is like a special doorway for your cable. It lets the cable go into a box or machine safely. It holds the cable tight. It stops bad things from getting in.

We are a cable gland maker in China. We make lots of these super helpers! We make:

- Plastic water proof cable glands

- Metal water proof cable glands

- Multi hole cable glands (for more than one cable!)

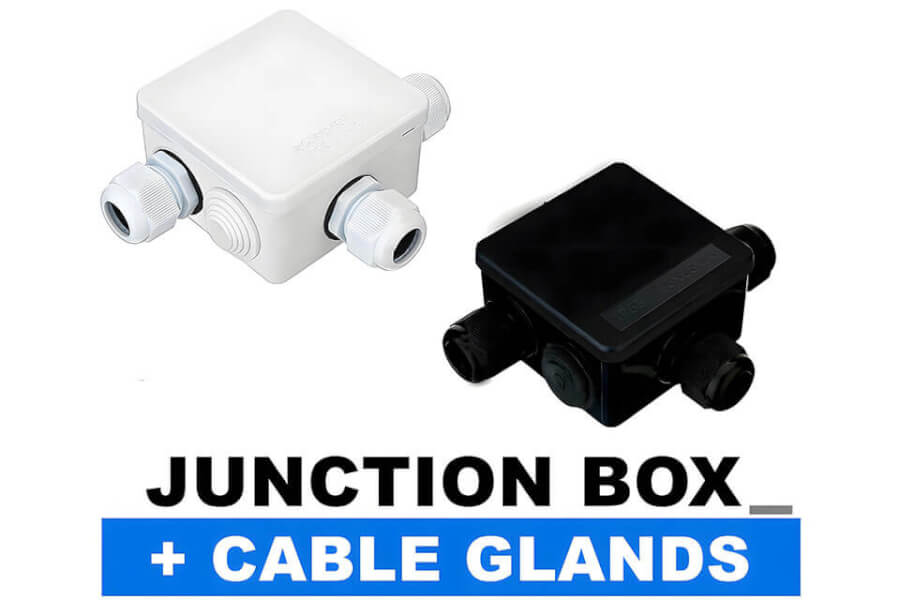

- Junction boxes (the boxes the cables go into!)

Our cable glands help keep your cables safe and working right. Let’s learn more about them!

1. What is a Cable Gland? (Your Cable’s Best Friend!)

Imagine a tiny tunnel. A cable gland is like that tunnel for your cable. It connects the cable to a piece of equipment, like an electrical box.

What does it do?

- Holds the cable: It grips the cable so it doesn’t get pulled out. This is called strain relief.

- Keeps bad stuff out: It makes a tight seal. This stops water, dust, dirt, and bugs from getting inside the box. This is called sealing or environmental protection.

- Keeps things safe: In some places, it stops sparks from escaping. This is very important in places with gas or dust that can explode. This is called safety.

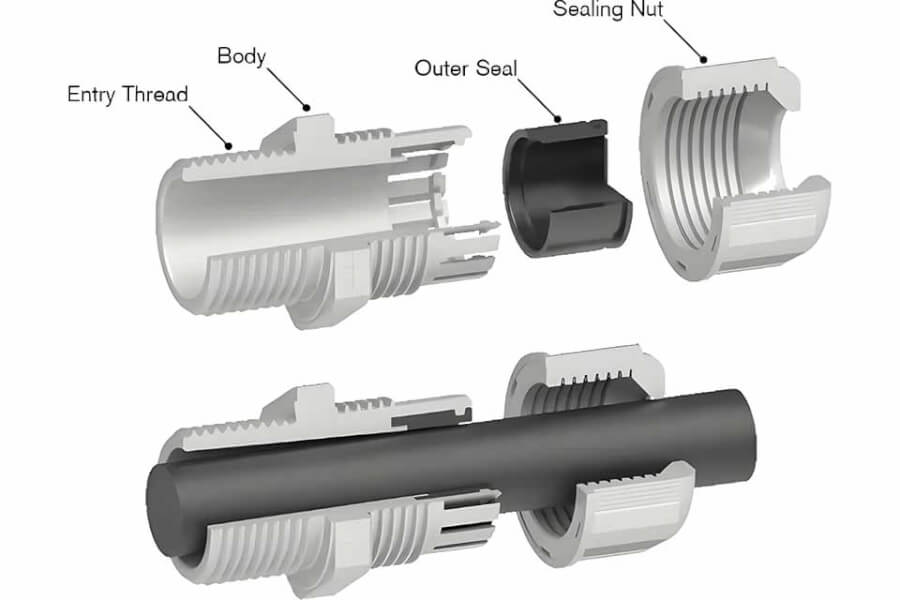

What are the parts of a cable gland? A cable gland has a few small parts that work together:

- Body: The main part you see.

- Seal: A rubbery ring that squeezes the cable to make it waterproof.

- Nut: A part you tighten to make the seal work.

- Locknut: A part that holds the gland tight to the box.

What kinds are there? There are many types! It depends on the cable and where you use it.

- Plastic Glands: These are light and don’t rust. Good for many places. We make great

plastic water proof cable glandoptions! - Metal Glands: These are very strong. Often made of brass or stainless steel. Good for tough spots or when you need extra safety. Check out our strong

metal water proof cable glandselection. - Armored Glands: For special cables that have metal armor for protection.

- Unarmored Glands: For regular cables without armor.

- Waterproof Glands: They have special seals to keep water out. Look for an IP rating like IP68. IP68 means it can even go under water!

- Explosion-Proof Glands (ATEX/IECEx): Super safe glands for places where explosions could happen. They stop sparks! Our

Brass Cable Glandis designed for these dangerous areas. - Multi-Hole Glands: Have more than one hole! Perfect when you need many cables to go into one spot safely. We offer convenient

multi hole cable glandsolutions.

(Problem) Choosing the right type is very important. Using the wrong one means it might not work! (Agitate) Imagine using a plastic gland where you need a strong metal one. It could break! Or using a normal gland where you need an explosion-proof one. That’s dangerous! (Solution) We can help! As a top manufacturer in China, we know cable glands. We make all these types. We can help you pick the perfect gland for your cable and your job.

2. How to Put a Cable Gland On (Easy Steps!)

Putting a cable gland on is called installation. It needs to be done right! If not, it might leak or not hold the cable tight.

(Problem) Doing installation wrong can cause big headaches later. (Agitate) A leaky gland means water gets in. Rust! Damage! A loose gland means the cable can pull out. Broken wires! Things stop working! This wastes time and money. (Solution) Follow these simple steps using a good quality gland, like the ones we make!

What tools do you need?

- Your cable gland (make sure it’s the right size!)

- A wrench or spanner (maybe two) to tighten the parts.

- Sometimes, a tool to cut the cable clean.

Simple Steps for Installation:

- Pick the Right Gland: This is key! The gland must fit your cable diameter. Not too big, not too small. Check the sizing information.

- Prepare the Cable: You might need to carefully cut off a little bit of the outer plastic layer (the sheath) of the cable. Don’t cut the wires inside!

- Put Gland Parts On: Slide the gland’s nut and body onto the cable.

- Put Cable In Box: Push the cable end through the hole in your box or equipment.

- Attach the Gland: Put the main body of the gland into the hole. Use the locknut on the inside of the box to hold it tight.

- Tighten the Nut: Now, tighten the outer nut. This squeezes the seal around the cable. Make it snug, but don’t overtighten! Overtightening can hurt the cable or the gland. Use the right force (sometimes a special wrench called a torque wrench helps).

- Check Your Work: Gently pull the cable. Does it feel secure? Look at the seal. Does it look tight all around? Good!

Pro Tip: For really wet or dirty places, you can use an extra rubber washer or special sealant paste around the gland where it meets the box for even better environmental protection.

Remember: Using high-quality glands makes installation easier and safer. Our glands are made carefully to fit right and seal tight.

3. Why Use a Cable Gland? (Super Benefits!)

Why bother with this little part? Because the benefits are HUGE! Using a cable gland solves many problems.

(Problem Recap) Remember? Cables are weak! Water, dust, pulling, sparks = bad! (Agitate Recap) Damage! Downtime! Danger! Costs! Worry! (Solution Recap) Cable glands are the answer! They offer:

Keeps Bad Stuff Out (Environmental Protection):

- Problem: Water, rain, splashing, dust, dirt, bugs can get into your electrical box.

- Agitate: This causes rust, short circuits, and equipment failure. Think of costly repairs!

- Solution: Cable glands create a tight seal. Waterproof cable glands (like IP68) stop water completely. Our plastic and metal waterproof glands give you great sealing performance. This keeps your equipment safe and dry.

Keeps People Safe (Safety):

- Problem: In some areas (like oil refineries, chemical plants, flour mills), gases or dust in the air can catch fire or explode from a tiny spark.

- Agitate: An explosion is a disaster! It can hurt people and destroy property. Using the wrong parts can lead to huge fines or shutdowns.

- Solution: Special explosion-proof cable glands (rated ATEX or IECEx) are needed. They are built strong to contain any sparks inside the box and prevent ignition outside. We manufacture ATEX compliant glands to meet these strict safety standards. Choosing the right gland type is critical for safety.

Holds Cables Tight (Mechanical Security / Strain Relief):

- Problem: Cables can get pulled, vibrate, or bend sharply where they enter a box.

- Agitate: This can damage the wires inside, loosen connections, or even pull the cable right out! This leads to failures that can be hard to find and fix.

- Solution: Cable glands grip the cable firmly. This strain relief stops the cable from being pulled or bent too much at the connection point. Our glands provide reliable mechanical security.

The cable glands market is growing fast! Experts think it was worth around USD 1.97 billion in 2024 and could reach over USD 3.1 billion by 2033. That’s a growth rate (CAGR) of about 5% to 7% per year. Why? Because more people understand these benefits! From aerospace to telecom to new construction, everyone needs reliable cable protection.

Table: Cable Gland Market Growth

| Year | Estimated Market Size (USD Billion) | Key Drivers | Source(s) |

|---|---|---|---|

| 2024 | ~ $1.9 – $2.4 | Telecom, Construction, Safety | |

| 2030 / 2033 | ~ $2.8 – $4.5 | Increased Automation, Renewables | |

| CAGR | ~ 5.0% – 6.8% | Growing Awareness of Benefits |

(Note: Market size estimates vary slightly between reports)

Using the right cable gland isn’t just a good idea; it’s often required by rules and standards. It protects your investment and keeps people safe.

4. Common Mistakes to Avoid (Don’t Do This!)

Putting in a cable gland seems easy, but small mistakes can cause big problems.

(Problem) Making mistakes during installation or selection means the gland won’t do its job right. (Agitate) Think about a brand new machine failing just because someone used the wrong size gland! Or a safety inspection failing because the glands weren’t the right type for a hazardous area. This leads to delays, rework, and frustration. You might even void the warranty on your equipment! (Solution) Know the common mistakes and avoid them! Choose quality glands from a trusted manufacturer like us.

Here are mistakes people often make:

Wrong Gland Type:

- Mistake: Using an indoor gland outside where it will get wet. Using a plastic gland where a strong metal one is needed. Using a standard gland in an area that needs an explosion-proof (ATEX) one.

- Result: Leaks, breaks, corrosion, major safety risks!

- Fix: Always match the gland type to the environment and the safety needs. Check the standards required.

Incorrect Sizing:

- Mistake: Choosing a gland too big for the cable. Or too small.

- Result: If too big, the seal won’t be tight. Water and dust get in! No proper strain relief. If too small, you might damage the cable trying to force it in, or you won’t be able to tighten the seal correctly.

- Fix: Measure your cable diameter carefully. Check the gland’s size range (it usually says “fits cables Xmm to Ymm”). Choose the gland where your cable size fits comfortably in the middle of that range.

Ignoring Standards:

- Mistake: Not checking what rules or codes apply to your installation. Different industries and countries have different standards (like IEC, NEC, UL, ATEX).

- Result: Your work might fail inspection. It could be unsafe. You might face fines.

- Fix: Know the required standards for your job (like IEC 62444 for general installation or ATEX for hazardous areas). Use glands that are certified to meet those standards. Our glands are made to meet tough international standards.

Poor Installation:

- Mistake: Not tightening the gland enough, or tightening it too much. Forgetting a part like the locknut or seal. Getting dirt on the seal.

- Result: Leaks! Loose cables! Damaged glands or cables!

- Fix: Follow the installation steps carefully (see section 2). Keep parts clean. Tighten correctly – snug but not crushed.

Bad Maintenance:

- Mistake: Never checking the glands after they are installed.

- Result: Over time, seals can dry out, metal can corrode, plastic can crack (especially in sunlight). The gland stops working well.

- Fix: Check glands sometimes, especially in tough environments. Look for cracks, rust, or loose parts.

Avoiding these mistakes helps your cable glands do their job perfectly for a long, long time. Choosing quality parts from the start makes everything easier.

5. Cable Gland Rules and Tests (Standards & Certifications)

How do you know if a cable gland is good and safe? You look for standards and certifications! These are like special stamps of approval.

(Problem) With so many glands out there, how do you know which ones are reliable and meet safety rules? (Agitate) Using a cheap, untested gland might save a little money now, but it could lead to huge costs later if it fails. Imagine equipment damage or, worse, an accident because a non-compliant part was used! Inspectors look for these certifications. Without them, your project might be stopped. (Solution) Choose glands from manufacturers who test their products and meet important standards. We take standards seriously! Our glands are designed and tested to meet global requirements.

Here are some important standards and ratings to know:

IP Ratings (Ingress Protection):

- This tells you how well the gland keeps out dust and water. It has two numbers (like IP68).

- First Number (Dust): 6 is the best, meaning totally dust-tight.

- Second Number (Water): 6 means protected from strong water jets. 7 means it can be underwater for a short time. 8 means it can be underwater continuously (IP68 is very waterproof!).

- Why it matters: You need the right IP rating for your environment. IP68 is great for outdoors, wet areas, or underground.

ATEX / IECEx (Explosion Protection):

- These are standards for equipment used in places with explosive atmospheres (gases, vapors, dust). ATEX is mainly used in Europe, IECEx is international.

- Why it matters: If you work in oil & gas, mining, chemical plants, etc., you MUST use ATEX or IECEx certified glands. They are designed to prevent explosions. Using the wrong gland here is extremely dangerous. The market for these special explosion-proof glands was estimated at around USD 168 million in 2024 and is growing.

UL / NEMA (North America):

- UL (Underwriters Laboratories) is a major safety testing organization in North America. NEMA (National Electrical Manufacturers Association) sets standards for enclosures and connections.

- Why it matters: If your equipment is going to the USA or Canada, look for UL listed or NEMA rated glands to ensure compliance.

IEC 62444 (Global Standard):

- This is an international standard specifically for the design and testing of cable glands.

- Why it matters: Glands meeting this standard have passed tests for things like strain relief, sealing (IP rating), and strength. It shows good quality.

(Solution) As a dedicated manufacturer, we ensure our products meet relevant standards. Whether you need IP68 waterproof protection or ATEX compliance for hazardous areas, we have glands tested and ready for your needs. We provide documentation showing our compliance, giving you peace of mind.

6. Fixing Problems (Troubleshooting FAQs)

Even with good glands, you might have questions. Here are some common ones:

(Problem) Help! My gland isn’t working right! (Agitate) Leaks? Loose cables? It’s frustrating when things don’t work as expected. You need answers fast! (Solution) Let’s look at common issues and how to fix them.

Q: “Can I reuse an old cable gland?”

- A: Maybe, but be careful. If the gland looks perfect (no cracks, no rust, threads are good), you might reuse it. BUT, it’s usually best to replace the rubbery seal inside. Old seals can get hard or cracked and won’t seal well. If the gland is damaged at all, replace the whole thing. It’s safer!

Q: “Why is my cable gland leaking water?”

- A: This usually happens for a few reasons:

- Wrong Size: The gland is too big for the cable, so the seal can’t grip tightly.

- Not Tight Enough: The compression nut wasn’t tightened enough to squeeze the seal.

- Overtightened: Tightening too much can damage the seal or the gland itself.

- Damaged Seal: The seal might be cut, cracked, or dirty.

- Wrong Gland Type: Maybe you used a gland with a low IP rating in a very wet place.

- Fix: Check the sizing. Make sure it’s tightened correctly (snug!). Inspect the seal. Replace the gland if needed with the correct IP rating. Our IP68 waterproof glands offer excellent protection against leaks.

- A: This usually happens for a few reasons:

Q: “Can I put more than one cable through a single gland?”

- A: Usually, no. Standard glands are designed for one cable. Trying to stuff multiple cables in will ruin the seal and strain relief. It won’t be waterproof or safe.

- Fix: If you need multiple cables in one spot, use a special multi-hole cable gland! These are designed with separate holes and seals for each cable. We manufacture

multi hole cable glandtypes that solve this exact problem safely and neatly.

Q: “The cable still moves even when the gland is tight!”

- A: This likely means the gland size is wrong for the cable (too big), or the gland is not designed for good strain relief. Make sure you have the correct size and a quality gland.

If you have problems, check these common causes first. Using quality glands from the start often prevents these issues.

7. When Should I Replace a Cable Gland?

Cable glands are tough, but they don’t last forever, especially in hard conditions.

(Problem) How do I know if my cable gland is old and needs changing? (Agitate) An old, worn-out gland can fail suddenly. This could let water in, cause a connection to fail, or even create a safety hazard without warning! Don’t wait for a failure to happen. (Solution) Look for signs that it’s time for a replacement. Replacing them proactively keeps things safe and reliable.

Look for these signs:

- Cracks: Check the gland body (especially plastic ones) for any cracks.

- Rust or Corrosion: Metal glands (especially brass if not plated well) can corrode over time, especially in wet or salty air. Stainless steel lasts longer but can still corrode in very harsh chemicals. Our

Stainless Steel Cable Glandoffers superior corrosion resistance. - Damage: Any visible damage from being hit or crushed.

- Loose Parts: If the nuts won’t stay tight or parts feel loose.

- Brittle Seal: If you can see the rubber seal and it looks dried out or cracked.

- UV Damage: Plastic glands used outdoors in direct sunlight can become brittle over many years due to UV rays. Choose UV-resistant plastic if needed.

Also consider the environment:

- Harsh Chemicals: If the gland is exposed to strong chemicals.

- Extreme Temperatures: Very high or very low temperatures can affect seals and materials.

- Lots of Vibration: Constant shaking can wear parts out faster.

Rule of thumb: If a gland looks old, damaged, or questionable, it’s best to replace it. Use a new, high-quality gland from a trusted manufacturer like us to ensure continued protection.

8. Where Are Cable Glands Used? (Top Use Cases)

You find cable glands almost everywhere electricity is used safely and reliably!

(Problem) Where do I actually need these things? (Agitate) Not using a gland where it’s needed can lead to all the problems we discussed: water damage, dust contamination, loose cables, safety hazards. Knowing where they are essential helps you plan your projects correctly. (Solution) Cable glands are critical in many applications. Here are some common examples where our glands provide excellent solutions:

Industrial Control Panels / Machinery:

- Factories use lots of machines with electrical boxes. Cable glands protect the wiring going into these boxes from dust, oil, water spray, and vibration. Metal glands are often used here for strength. Our sturdy metal waterproof cable glands are perfect for this. Junction boxes are also key components here, and we supply quality

junction boxoptions too.

- Factories use lots of machines with electrical boxes. Cable glands protect the wiring going into these boxes from dust, oil, water spray, and vibration. Metal glands are often used here for strength. Our sturdy metal waterproof cable glands are perfect for this. Junction boxes are also key components here, and we supply quality

Outdoor Lighting and Signs:

- Streetlights, garden lights, illuminated signs – they all face the weather. Waterproof cable glands (like IP68) are essential to keep rain and moisture out of the electrical connections. Our plastic waterproof cable glands are a great, cost-effective choice here.

Solar Panel Installations:

- Solar panels sit outside for decades. The wiring needs protection from rain, sun, and temperature changes. IP68, UV-resistant cable glands are crucial for connecting panels and inverters reliably.

Marine and Offshore:

- Ships, docks, and oil rigs are very harsh environments with saltwater spray and constant moisture. Corrosion-resistant glands (like stainless steel or nickel-plated brass) with high IP ratings are a must.

Hazardous Areas:

- Oil refineries, chemical plants, mines, fuel stations need explosion-proof (ATEX / IECEx) glands to prevent sparks from causing fires or explosions. Safety is the top priority here.

Telecommunications:

- Equipment shelters and connection boxes need protection from the elements to keep phone and internet services running.

Construction and Underground Wiring:

- Wherever cables enter buildings or run underground, glands provide necessary sealing and strain relief.

Basically, anywhere a cable needs to enter an enclosure safely and be protected from its surroundings, a cable gland is the right tool for the job!

9. Conclusion: Yes, Use a Cable Gland!

So, can a cable go through a gland? Absolutely YES! That’s their main purpose.

(Problem Recap) We learned that unprotected cables entering boxes face risks from water, dust, pulling, and even dangerous sparks. (Agitate Recap) These risks lead to equipment failure, costly downtime, and serious safety hazards. (Solution Recap) Cable glands are the essential solution! They provide:

- Environmental Protection (sealing against dust and water – IP ratings)

- Mechanical Security (strain relief)

- Enhanced Safety (especially ATEX/IECEx glands in hazardous areas)

Key Takeaways:

- Always use a cable gland when a cable enters an enclosure, especially outdoors or in industrial settings.

- Choose the right type and size for your cable and environment. Consider materials (plastic, brass, stainless steel), IP rating, and any special needs (like ATEX).

- Install it correctly! Follow the steps, tighten properly, and keep parts clean.

- Don’t ignore standards! Use certified glands where required.

- Check them sometimes and replace if they look damaged or worn out.

We Can Help! As a leading cable gland manufacturer in China, we are experts in cable protection. We offer a wide range of high-quality products:

- Durable

plastic water proof cable gland - Robust

metal water proof cable gland(Brass, Stainless Steel) - Convenient

multi hole cable gland - Reliable

junction boxsolutions

Our products meet international standards, providing the safety, sealing, and strain relief you need. We understand the problems you face and provide the solutions to keep your connections secure and your operations running smoothly.

Final Tip: When in doubt, always check the manufacturer’s instructions for your cable gland and the requirements for your specific application. Making the right choice protects your equipment and keeps everyone safe! Visit our main site to explore all cable gland options.

News & Blog

Discover what cable glands are, why they matter, and how the right choice protects cables, boosts safety, and ensures reliable performance in any environment.