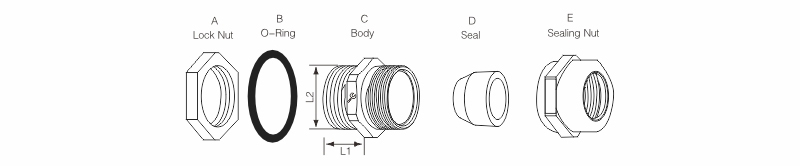

Non-armored Cable Gland

What is a Non-Armored Cable Gland?

A non-armored cable gland is a tool that holds wires tight. It keeps wires safe when they go into boxes or walls. Our glands work with wires that do not have metal on the outside.

Why Pick Our Cable Glands?

- Safe for bad places – Works where gas or dust might blow up

- Stops water and dust – Keeps IP66/67 rating to block out bad stuff

- Holds wires tight – No more loose wires that pull and break

- Works in hot and cold – Good from -20°C to +100°C

Types We Sell

| Type | What It’s Made Of | Where to Use It | Cool Facts |

|---|---|---|---|

| Basic | Plastic | Homes, small shops | Keeps dust out with IP64 rating |

| Pro | Brass with nickel | Big machines, wet spots | Stops water with IP66/67 |

| Tough | Stainless Steel | Oil rigs, sea ships | Works in salt water |

| Safe | Brass or Plastic | Gas plants, dust mills | Stops sparks from making fires |

Where to Use Our Glands

- Homes – Keep kids safe from loose wires

- Shops – Hold tight in tool boxes

- Big Plants – Stop dust and gas from making boom

- Wet Spots – Keep water out of wire boxes

- Hot Places – Work fine when it’s hot

Why Our Glands Are Best

Our non-armored cable glands have good marks from big test groups:

- ATEX says yes

- IECEx says good

- NEC 501 says safe They work in Zone 1, Zone 2, Zone 21, and Zone 22 where bad stuff like gas or dust can blow up.

More Cool Things

- EMC types stop bad waves that hurt wire talk

- Spiral bits stop wires from bend too much

- Metal ones have a seal that stops fire from going through

Pick the Right Gland

Not sure which cable gland to get? Check out our other great picks:

- for big jobs

- Plastic glands that block water for home use

- Glands with lots of holes when you have many wires

Get the Whole Set

Need a place to put your wires after the gland? Check out our safe junction boxes that work with all our glands!

Why Trust Us

We make the best cable glands that:

- Stop strain on wires

- Work in hot and cold

- Keep dust and water out

- Stop fire from gas and dust

- Fit both plastic and metal boxes

Get Yours Now!

Visit our main cable gland shop to see all the types we sell. Note: Pick the right size for your wire! If you need help, just ask us.

Inquiry

Specification

Product Specification

| Product Name | Non armored explosion-proof joint |

| working temperature | -50 ℃ to 120 ℃ |

| Protection level | IP66 |

| Certificate | SYEx24.0123X |

| Product performance | Waterproof, dustproof, salt resistant, acid and alkali resistant, alcohol, grease and general solvents. |

| Cable range selection | See table parameters for details |

| Scope of application | Suitable for Zone 1 and Zone 2 explosive gas environments Suitable for Zone 21 and Zone 22 environments with combustible dust; Suitable for IIA, IB, IIC explosive gas environments: Widely used in explosive hazardous areas such as petroleum extraction, storage, chemical, pharmaceutical, military, and military facilities: As a supporting accessory for explosion-proof electrical equipment, it is used to clamp various armored or non armored cables. |

Technical Parameter

| Thread specification | Cable Range (B) (mm) | Thread (C) (mm) | Length (L) (mm) | ||

|---|---|---|---|---|---|

| M | G | NPT | |||

| M12x1.5 | G1/4″ | NPT1/4″ | 3~6.5 | 12 | 52 |

| M16x1.5 | — | — | 5~10 | 15 | 52 |

| M20x1.5 | G1/2″ | NPT1/2″ | 9~15 | 15 | 52 |

| M25x1.5 | G3/4″ | NPT3/4″ | 14~20 | 15 | 52 |

| M32x1.5 | G1″ | NPT1″ | 19~25 | 17 | 52 |

| M40x1.5 | G1-1/4″ | NPT1-1/4″ | 25~32 | 17 | 54 |

| M50x1.5 | G1-1/2″ | NPT1-1/2″ | 35~40 | 17 | 59 |

| M63x1.5 | G2″ | NPT2″ | 45~50 | 17 | 59 |

| M75x1.5 | G2-1/2″ | NPT2-1/2″ | 56~65 | 17 | 78 |

| M90x2 | G3″ | NPT3″ | 64~75 | 17 | 78 |

| M115×2 | G4″ | NPT4″ | 78~92 | 17 | 82 |

Frequently Asked Questions About Cable Gland

We have not set a minimum MOQ, we customize products according to customer needs. In theory, we can meet different MOQ requirements of customers, but different MOQs will have different costs.

Normally our lead time is 1~2 weeks for batch production. For urgent case, we can improve it in 3~7 days.

We do need the dimention, colour, thread, material, certification, and more applications will be helpful.

We have CE, TUV and UL certificates.

Certainly, we can supply you the free standard samples according your requirement.