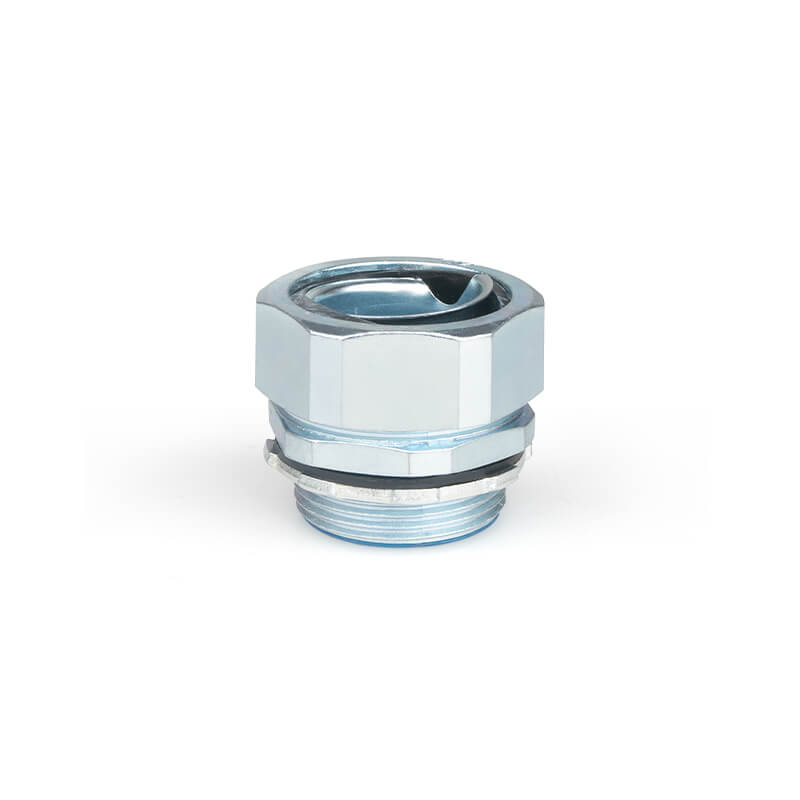

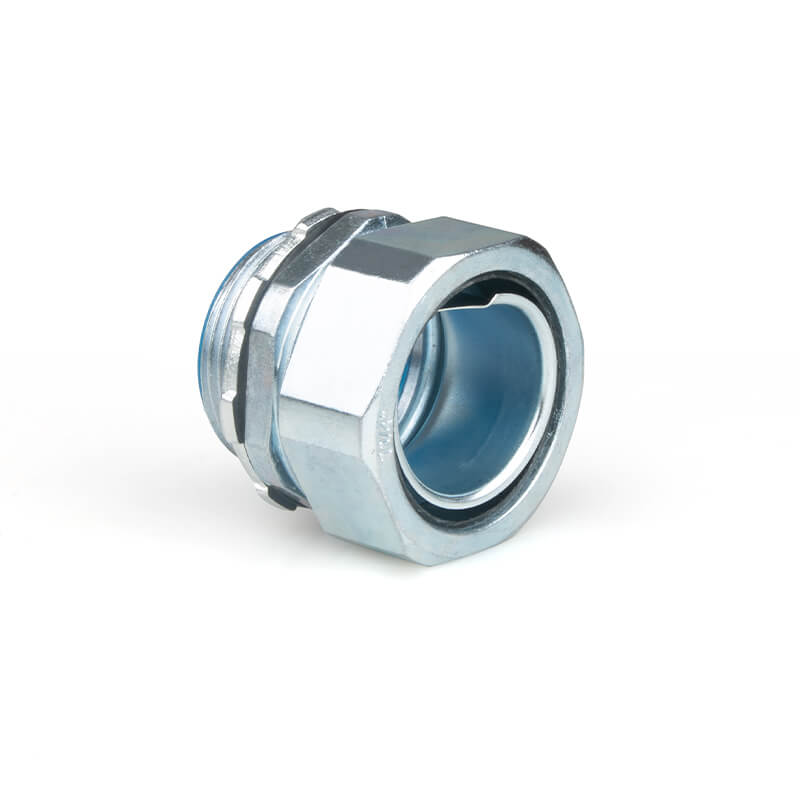

Metal Hose Connectors DPJ Series IP65 Customization

Need hose connectors that won’t quit under pressure? Our extra-strong metal connectors (made of stainless steel and brass) work great in tough places like factories, oil fields, construction zones, and heavy-duty gardens. They won’t break or leak, even with high water pressure, chemicals, or extreme hot/cold temperatures.

Why these connectors work better:

- No leaks ever: Double-layer seals stop drips (even with harsh chemicals!)

- Fits anything: Works with US, European, and Asian equipment threads

- Lasts years: Won’t rust or break like plastic or cheap metal fittings

- Easy to install: Swivels 360° to avoid twisted hoses

Need waterproof cable protection too? Check our metal cable glands.

Built to Last in Tough Environments

Problem: Regular connectors rust or break too fast

Our solution:

- Stainless steel shell resists scratches and weather

- Brass core won’t crack under heavy use

- Handles temperatures from freezer-cold (-40°F) to oven-hot (750°F)

Where people use them:

- Pumping oil on offshore rigs

- Moving chemicals in factories

- High-pressure water in mines

- Even tough garden/agricultural jobs

“These survived 2 years on our mining pumps – zero leaks!” – Equipment Manager, Copper Mine

For messy worksites, pair with our multi-hole cable organizers.

Works with All Your Equipment

Problem: Threads don’t match your machines

Our fix:

- 3 thread types in one: Fits American (NPT), European (BSPP), and Asian pipes

- Swivel head turns freely – no more struggling to screw on

- Same connector works for water hoses, air lines, and chemical pipes

Examples:

- Connect factory machines from different countries

- Fix broken garden irrigation systems fast

- Repair ship engine cooling lines

Handles Extreme Pressure Without Bursting

Problem: Cheap connectors explode under pressure

Our safety features:

- 6,000 PSI rating (regular garden connectors fail at 300 PSI!)

- Reinforced metal braid prevents bulging

- Smooth inner lining keeps water flowing fast

Pressure test results:

| Use Case | Standard Connector | Our Connector |

|---|---|---|

| Factory hydraulics | Fails at 1,200 PSI | Works at 6,000 PSI |

| Mine water pump | Lasts 3 months | Lasts 2+ years |

Need explosion-proof parts? See our industrial junction boxes.

Need explosion-proof parts? See our industrial junction boxes.

Get Your Unbreakable Connectors Today

Available in 25+ sizes – from small garden fixes to giant factory installations. Bulk discounts for construction companies and mines.

Why wait? ➔ Free shipping on orders over $500 ➔ 5-year warranty against leaks/breaks ➔ Expert help choosing the right size

Chat with our hose experts now →

TL;DR: Unbreakable hose connectors that stop leaks forever – trusted by factories, mines, and farms worldwide.

Inquiry

Specification

Thread specifications: PG/M/G.

Product Material:

Parts A, C, F: High-quality thickened zinc alloy.

Parts B, E: Nitrile rubber.

Part D: Iron sheet.

Color: Metallic (silver white).

Working temperature: -40 °C to +100 °C (short-term up to +120 °C).

Protection level: IP65.

Product features:

Thickened zinc alloy with galvanized or chrome plating; aesthetically pleasing, compact, and high-strength.

Hose sheath design ensures tight connection, easy assembly, and strong tensile strength.

Waterproof, dustproof, resistant to salt, acid, alkali, alcohol, oil, grease, and general liquids.

Customizable size and thread standards upon request.

| Technical Parameters | |||||||

| Suitable Metal Flexible Pipe | Spiral Tooth Standard | Thread O.D. | Thread Length | Joint Length | |||

| Metric | G System | Metric | G System | D1 (mm) | L1 (mm) | L2+L3 (mm) | |

| Φ6 | 3/16″ | M14x1.5 | G1/4″ | PG7 | 13.2 | 8 | 16 |

| Φ8 | 1/4″ | M16x1.5 | G3/8″ | PG9 | 13.2 | 8 | 16 |

| Φ10 | 5/16″ | M16x1.5 | G3/8″ | PG9 | 16.5 | 8 | 17 |

| Φ12(13) | 3/8″ | M20x1.5 | G3/8″ | PG11/PG13.5 | 16.5 | 8 | 18 |

| Φ15(16) | 1/2″ | M20x1.5/M24x1.5 | G1/2″ | PG13.5/PG16 | 21.3 | 11 | 23 |

| Φ20(19) | 3/4″ | M27x2.0/M30x2.0 | G3/4″ | PG21 | 26.6 | 14 | 22 |

| Φ25 | 1″ | M33x2.0/M36x2.0 | G1″ | PG29 | 33.4 | 15 | 28 |

| Φ32 | 1-1/4″ | M42x2.0/M48x2.0 | G1-1/4″ | PG29 | 42.1 | 15 | 30 |

| Φ38(40) | 1-1/2″ | M48x2.0/M60x2.0 | G1-1/2″ | PG36/PG42 | 47.8 | 16 | 32 |

| Φ51(50) | 2″ | M60x2.0/M70x2.0 | G2″ | PG48 | 59.6 | 18 | 34 |

| Φ64(70) | 2-1/2″ | M76x2.0 | G2-1/2″ | – | 75.1 | 22 | 38 |

| Φ75(80) | 3″ | M88x2.0 | G3″ | – | 87.8 | 22 | 46 |

| Φ100 | 4″ | M114x2.0 | G4″ | – | 113 | 24 | 50 |

| Φ125 | 5″ | M140x2.0 | G5″ | – | – | – | – |

| Φ150 | 6″ | M164x2.0 | G6″ | – | – | – | – |

Frequently Asked Questions About Cable Gland

We have not set a minimum MOQ, we customize products according to customer needs. In theory, we can meet different MOQ requirements of customers, but different MOQs will have different costs.

Normally our lead time is 1~2 weeks for batch production. For urgent case, we can improve it in 3~7 days.

We do need the dimention, colour, thread, material, certification, and more applications will be helpful.

We have CE, TUV and UL certificates.

Certainly, we can supply you the free standard samples according your requirement.