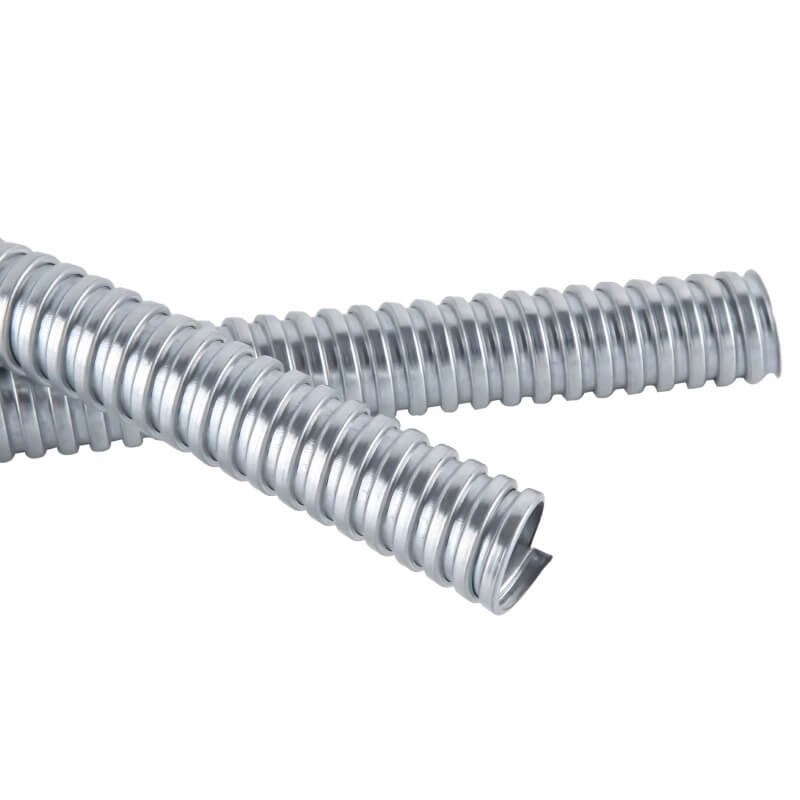

JS Series Liquid Tight Flexible Conduit Connector Galvanized Metal Hose

Why Choose JS Series Connectors?

JS Series Liquid Tight Flexible Conduit Connectors protect wires in tough places. They work in rain, snow, heat, and cold.

Key Features:

- Strong Build: Metal core and tough plastic cover keep wires safe.

- Works Everywhere: From -40°C cold to +80°C heat.

- No Leaks: IP68/IP69K rating stops water and dust.

- Easy to Use: Twist-in design with grounding lugs.

- Safe for Factories: UL, CSA, and NEC approved.

Technical Specs

| Feature | Details |

|---|---|

| Temperature Range | -40°C to +80°C |

| Voltage Rating | Up to 1,000 V |

| Sizes | 3/8″ to 4″ |

| Material | Metal core + UV-proof PVC |

| Certifications | UL 514B, CSA, NEC |

| IP Rating | IP68/IP69K |

| RoHS Compliance | Yes |

| Pressure Resistance | 750 psi |

Where to Use JS Series Connectors

1. Outdoor Lighting & Signs

- Fix wires to signs, streetlights, or garden lights.

- Survives rain, snow, and sun.

Pair with: Plastic waterproof cable glands for extra weather protection.

2. Factories & Machines

- Connect wires to robots, ovens, or tools.

- Resists oil, dirt, and shaking.

Pair with: Metal waterproof cable glands for heavy-duty machines.

3. Food & Drink Plants

- Safe for washdowns and sanitizers.

- No rust or cracks.

Pair with: Multi-hole cable glands for messy areas.

4. Boats & Farms

- Stops saltwater or mud from damaging wires.

- Lasts years in wet barns or docks.

Pair with: Junction boxes to organize cables.

Benefits for You

- Safety First

- Approved for hazardous locations (Class I Div.2).

- No sparks or leaks in oil/gas plants.

- Lasts Longer

- Metal core won’t bend or break.

- Saves money over time.

- Easy to Install

- No tools needed.

- Fits LFMC, LFNC, and PVC.

- Works Worldwide

- UL (USA), CSA (Canada), and RoHS (Europe) approved.

Perfect Pairings

Boost your project with these CAGLAND products:

- Metal Waterproof Cable Glands: For factories and ships.

- Cable Gland Adaptors: Connect different sizes easily.

- Flexible Conduits: Bend wires around corners safely.

FAQs

Q: Does this fit plastic conduits?

A: Yes! Works with LFNC-A non-metallic conduits.

Q: Do I need extra sealant?

A: No – built-in gaskets stop leaks.

Q: Can I use this in ovens?

A: Yes! Handles heat up to +80°C.

Q: Where to buy?

A: Visit our Conduit Connectors & Fittings page.

Q: Are these safe for Canada?

A: Yes – CSA and NEC approved.

Custom Orders

Need special sizes or designs? Try our OEM/ODM service. We make connectors for:

- Solar farms.

- Data centers.

- Custom robots.

Call to Action:

Want UL-approved, leak-proof connectors? Shop JS Series now or ask about custom orders.

Inquiry

Specification

Product Specifications:

Material: Galvanized steel strip

Key Features:

✔ Lightweight yet durable

✔ Ultra-flexible with excellent bending performance

✔ Smooth interior for easy cable threading

Applications:

Wiring protection for machinery, buildings, and industrial facilities

Installation:

Thread cables through conduit

Match with DPJ series connectors

<!doctype>

| Technical Parameters | |||||

Model | Spec (mm) | G-System | Outer Ø ±Tol. (mm) | Natural Curve (mm) | Max. Axial Pull (Kg) |

| JS-6 | Φ6 | 3/16″ | 8.20±0.25 | 40 | 335 |

| JS-8 | Φ8 | 1/4″ | 11.0±0.30 | 45 | 470 |

| JS-10 | Φ10 | 5/16″ | 13.5±0.30 | 55 | 590 |

| JS-12 | Φ12 | – | 15.5±0.35 | 60 | 710 |

| JS-13 | Φ13 | 3/8″ | 16.5±0.35 | 65 | 765 |

| JS-15 | Φ15 | – | 19.0±0.35 | 80 | 885 |

| JS-16 | Φ16 | 1/2″ | 20.0±0.35 | 85 | 940 |

| JS-19 | Φ19 | – | 23.3±0.40 | 95 | 1120 |

| JS-20 | Φ20 | 3/4″ | 24.3±0.40 | 100 | 1180 |

| JS-25 | Φ25 | 1″ | 30.3±0.45 | 120 | 1450 |

| JS-32 | Φ32 | 1¼” | 38.0±0.50 | 150 | 1885 |

| JS-38 | Φ38 | 1½” | 45.0±0.60 | 180 | 2240 |

| JS-51 | Φ51 | 2″ | 58.0±1.00 | 220 | 3000 |

| JS-64 | Φ64 | 2½” | 72.5±1.50 | 310 | 3770 |

| JS-75 | Φ75 | 3″ | 83.5±2.00 | 350 | 4400 |

| JS-100 | Φ100 | 4″ | 108.5±3.00 | 410 | 4700 |

Frequently Asked Questions About Cable Gland

We have not set a minimum MOQ, we customize products according to customer needs. In theory, we can meet different MOQ requirements of customers, but different MOQs will have different costs.

Normally our lead time is 1~2 weeks for batch production. For urgent case, we can improve it in 3~7 days.

We do need the dimention, colour, thread, material, certification, and more applications will be helpful.

We have CE, TUV and UL certificates.

Certainly, we can supply you the free standard samples according your requirement.