Explosion-proof Cable Gland

What Are These?

These are special tools that keep you safe when you work with cables in risky places. They stop sparks that can cause big fires.

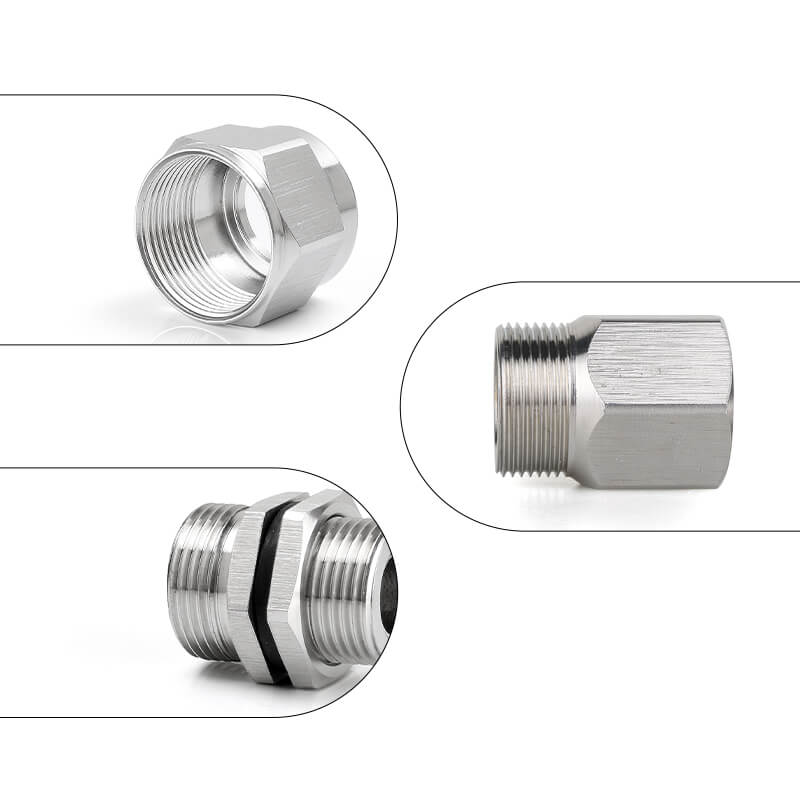

What They Are Made Of

- Stainless steel – Does not rust

- Brass – Strong and shiny

- Carbon steel – Very tough

- Safe plastic – Will not make sparks

Where To Use Them

| Place | Why You Need Them |

|---|---|

| Oil rigs | Stop gas fires |

| Mines | Keep dust from catching fire |

| Chemical plants | Protect from bad air |

| Gas plants | Safe with flammable gas |

Why Pick Our Cable Glands

- Stay dry – No water gets in (IP68 rated)

- Work in hot and cold – Good from -40°C to +120°C

- Fit many sizes – From M16 to M100

- Safe everywhere – ATEX, IECEx, UL certified

- Strong seals – Keeps gas and dust out

Types We Have

- Best for wet places

- Multi-hole cable glands – For many cables at once

- Ex d glands – For very risky spots

- Ex e glands – For safer but still risky spots

What Makes Ours Special

“Our ATEX-certified cable glands stop explosions with top seals. Used on oil rigs and in chemical plants all over the world.” Our glands are built to last in hard places. They work in salt water, dust, E bad weather. You can use one gland for many rules – ATEX, IECEx, E North American rules too.

How To Use Them

- Pick the right size for your cable

- Screw the gland into your scatola di giunzione

- Put your cable through

- Tighten it up

- Now it’s safe!

What Experts Say

The market for these will be worth $1.9 billion by 2033. More and more people in oil, gas, and mining need them to stay safe.

Need Help?

Visit our main passacavo page to see all we sell. We also have plastic waterproof cable glands for less risky spots.

Why Choose Our Explosion-Proof Cable Glands

- Safety first – No risk of fire

- Easy to use – Simple to set up

- Lasts long – Won’t break soon

- Works everywhere – In any tough spot

- Meets all rules – Passes all tests

Inchiesta

Specifica

Product Specification

| Product Name | explosion-proof armored stuffing box joint |

| working temperature | -50 ℃ to 120 ℃ |

| Protection level | IP66 |

| Certificate | SYEx24.0123X |

| Product performance | Waterproof, dustproof, salt resistant, acid and alkali resistant, alcohol, grease and general solvents. |

| Cable range selection | See table parameters for details |

| Scope of application | Suitable for Zone 1 and Zone 2 explosive gas environments Suitable for Zone 21 and Zone 22 environments with combustible dust; Suitable for IIA, IB, IIC explosive gas environments: Widely used in explosive hazardous areas such as petroleum extraction, storage, chemical, pharmaceutical, military, and military facilities: As a supporting accessory for explosion-proof electrical equipment, it is used to clamp various armored or non armored cables. |

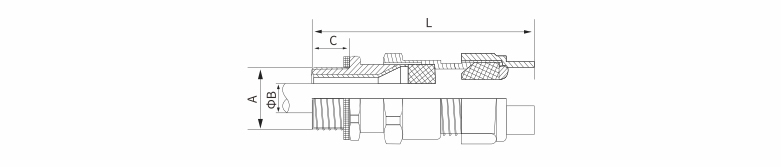

Technical Parameter

| Thread specification | Range of incoming lines (mm) | Maximum output line (mm) | L (mm) | A (mm) | Wrench Size A/B (mm) | ||

|---|---|---|---|---|---|---|---|

| M | G | NPT | |||||

| M16x1.5 | 5~8 | 12 | 87 | 16 | 24/26.5 | ||

| M20x1.5 | G1/2″ | NPT1/2″ | 5~15 | 12 | 87 | 16 | 24/26.5 |

| M25x1.5 | G3/4″ | NPT 3/4″ | 8~20 | 18 | 88 | 17 | 30/33 |

| M32x1.5 | 10~25 | 22 | 96 | 17 | 38/42 | ||

| M40x1.5 | G1¼” | NPT1¼” | 12~30 | 30 | 105 | 18 | 46/50 |

| M50x1.5 | G1½” | NPT1½” | 14~38 | 34 | 108 | 18 | 55/60 |

| M63x1.5 | G2″ | NPT2″ | 20~48 | 44 | 118 | 20 | 68/73 |

| M75x1.5 | G2½” | NPT 2½” | 24~58 | 52 | 124 | 20 | 84/92 |

| M88x1.5 | 30~70 | 65 | 128 | 20 | 97/105 | ||

| M100x1.5 | G3½” | NPT 3½” | 45~102 | 84 | 136 | 20 | 125/136 |

| M110x1.5 | 45~102 | 90 | 136 | 20 | 125/136 | ||

| M115x1.5 | G4″ | NPT4″ | 45~102 | 90 | 136 | 20 | 125/136 |

Domande frequenti sul pressacavo

Non abbiamo fissato un MOQ minimo, personalizziamo i prodotti in base alle esigenze del cliente. In teoria, possiamo soddisfare diversi requisiti MOQ dei clienti, ma diversi MOQ avranno costi diversi.

Normalmente il nostro tempo di consegna è di 1 ~ 2 settimane per la produzione in lotti. Per casi urgenti, possiamo migliorarlo in 3 ~ 7 giorni.

Abbiamo bisogno della dimensione, del colore, del filo, del materiale, della certificazione e altre applicazioni saranno utili.

Abbiamo certificati CE, TUV e UL.

Certamente, possiamo fornirti i campioni standard gratuiti in base alle tue esigenze.