Indice dei contenuti

Come scegliere il giusto pressacavo: Una guida passo-passo

Il problema: la scelta del pressacavo sbagliato

Lo fate preoccupazione di scegliere il pressacavo sbagliato? Molti lo fanno. I pressacavi difettosi possono causare grandi problemi. Possono far entrare l'acqua. Possono far rompere i fili. Possono persino innescare incendi!

Quando si sceglie il pressacavo sbagliato:

- L'acqua entra nella scatole

- I fili vengono danneggiato

- Il vostro lavoro non passa test

- Sprechi denaro sistemare tutto

Perché questo danneggia la vostra attività

Pensate a cosa succede quando un pressacavo si rompe. L'intero progetto si ferma! Il vostro capo si pazzo. I vostri clienti ricevono sconvolto. Si perde tempo e denaro.

Sapevate che 45% di tutti i problemi relativi ai cavi derivano dalla scelta della dimensione sbagliata? E che 30% derivano dalla scelta del materiale sbagliato? Ciò significa che la maggior parte dei problemi dei cavi potrebbe essere fermato se la gente sapesse come scegliere il giusto passacavo!

La cosa peggiore? Potreste accorgervi del problema solo quando è troppo tardi. Il danno da acqua richiede tempo per arrivare. A quel punto, la riparazione costa 5 volte di più!

La soluzione: I pressacavi personalizzati di CAGLAND

Buone notizie! CAGLAND fa di alta qualità pressacavi in Cina. Siamo in grado di realizzare qualsiasi tipo di prodotto. I nostri pressacavi:

- Tenere lontana l'acqua

- Tenere i cavi stretti

- Durata prolungata

- Costo inferiore agli altri

- Spedire velocemente a voi

Ora impariamo a scegliere il pressacavo giusto per non avere più questi problemi!

1. Conoscere i tipi di cavo

Innanzitutto, è necessario sapere che tipo di cavo avete.

Cavi unipolari e multipolari

Avete singolo nucleo cavi? Questi hanno bisogno di alluminio ghiandole. Perché? Perché altri metalli possono surriscaldarsi.

Avete multi-core cavi? La maggior parte dei pressacavi metallici funziona bene per questi cavi.

Cavi armati e non armati

I cavi corazzati necessitano di speciali premistoppa che mantengano l'armatura. Il nostro pressacavo metallico impermeabile è perfetto per questi lavori!

Vedere questa tabella:

| Tipo di cavo | Tipo di ghiandola migliore | Perché funziona |

|---|---|---|

| Singolo nucleo | Alluminio | Blocca il surriscaldamento |

| Multi-core | Ottone o nylon | Una buona scelta a tutto tondo |

| Corazzato | Metallo con morsetto | Mantiene salda l'armatura |

| Schermato | Tipo EMC | Blocca il rumore del segnale |

2. Misurare le dimensioni del cavo

Le dimensioni contano! Il motivo principale per cui i pressacavi si guastano è la dimensione sbagliata.

Come misurare:

- Prendete il vostro cavo

- Utilizzare un metro a nastro

- Avvolgerlo intorno al cavo

- Annotare le dimensioni

Tabella delle taglie:

| Dimensioni del cavo (mm) | Thread PG | Filettatura metrica |

|---|---|---|

| 3-6.5 | PG7 | M12 |

| 6-12 | PG13.5 | M20 |

| 12-18 | PG21 | M25 |

| 18-25 | PG29 | M32 |

| 25-33 | PG36 | M40 |

Ricorda: Non utilizzare mai il nastro adesivo per far combaciare un cavo. Questo infrange le regole e crea configurazioni non sicure!

3. Pensate a dove va il vostro cavo

Dove verrà utilizzato il vostro pressacavo? Questo aspetto è molto importante!

Interno vs. Esterno

Per l'uso all'aperto, è necessario impermeabile ghiandole. Il nostro pressacavo in plastica impermeabile funziona benissimo all'aperto!

Guida alla classificazione IP

| Luogo | Grado di protezione IP necessario | Cosa significa |

|---|---|---|

| All'interno di un edificio asciutto | IP54 | Resistente alla polvere e agli spruzzi |

| All'esterno | IP66 o IP67 | Resistente alla pioggia e alla polvere |

| Sott'acqua | IP68 | Può rimanere sott'acqua |

| Piante alimentari | IP69K | Può gestire spruzzi caldi |

Lo sapevate? I premistoppa IP68 bloccano i problemi legati all'acqua 95% meglio dei premistoppa standard!

4. Controllare le aree di pericolo

In alcuni luoghi ci sono gas che possono esplodere! Per questi luoghi sono necessarie delle ghiandole speciali.

Tipi di aree pericolose:

- Stazioni di servizio

- Piattaforme petrolifere

- Mulini per farina

- Impianti chimici

Per questi luoghi sono necessari i pressacavi certificati ATEX o IECEx. Questi impediscono alle scintille di provocare grandi incendi!

Fattore di sicurezza: I giusti premistoppa antideflagranti riducono il pericolo di 80% nelle aree a rischio.

5. Scegliere il tipo di filo giusto

I fili devono essere abbinati alla scatola o al piatto!

Tipi di filettatura comuni:

- Fili PG - Utilizzato in 40% di lavori in Europa

- Filettature metriche - Utilizzato in 55% di lavori a macchina

- Filettature NPT - Utilizzato in Nord America

Suggerimento: Guardate prima la vostra scatola. Poi scegliete un premistoppa con lo stesso filo.

6. Scegliere il materiale giusto

I materiali sono importanti per la durata della ghiandola!

Guida ai materiali:

| Materiale | Buono per | Male per |

|---|---|---|

| Ottone | La maggior parte dei lavori in interni/esterni | Aria molto salata |

| Plastica | Risparmio di costi, leggerezza | Luoghi molto caldi |

| Acciaio inox | Alimenti, prodotti chimici, sale | Costo (30% in più) |

| Alluminio | Cavi unipolari | Aree umide |

Un fatto interessante: I premistoppa in ottone sono utilizzati in 60% tutti i lavori industriali perché durano a lungo!

7. Esigenze speciali per lavori speciali

Alcuni lavori richiedono ghiandole speciali.

Cavi multipli

Avete bisogno di far passare molti piccoli cavi in un unico foro? Il nostro pressacavo multiforo risolve questo problema!

Protezione EMI

Lavorate con sistemi di controllo o motori? Per evitare problemi di segnale, sono necessari i pressacavi di schermatura EMI.

8. Come installare i pressacavi nel modo giusto

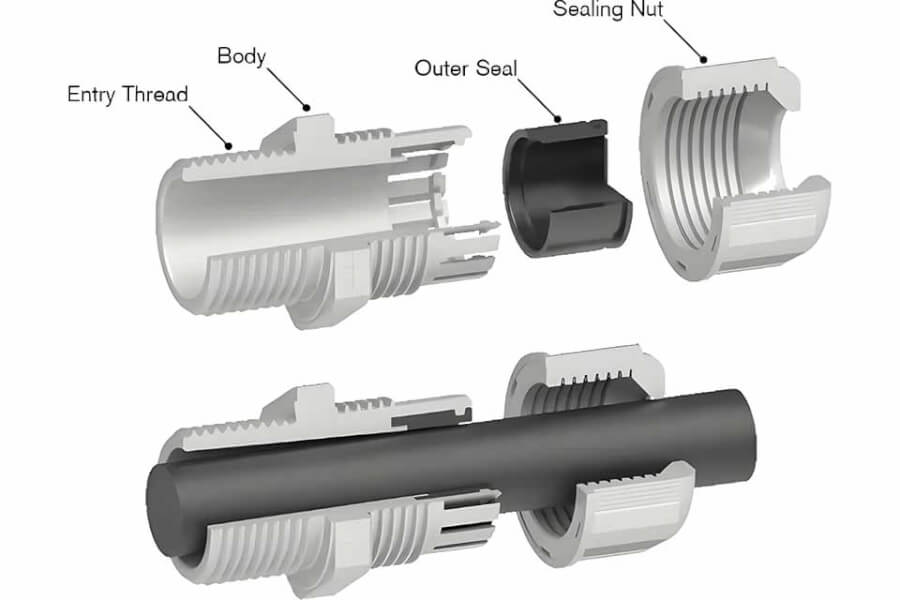

Scegliere il ghiandola giusta è solo il primo passo. Bisogna anche inserirla nel modo giusto!

Passi semplici:

- Tagliare il cavo alla giusta lunghezza

- Inserire le parti nell'ordine giusto

- Serrare alla giusta forza (25-30 Nm)

- Utilizzare grasso sulle guarnizioni per le aree umide

Lo sapevate? L'ingrassaggio delle guarnizioni le rende 50% più efficaci nel fermare l'acqua!

9. Errori comuni da evitare

Le persone commettono continuamente questi errori. Non siate uno di loro!

Grandi errori:

- Utilizzo della misura sbagliata: Questo causa il 45% di tutti i guasti.

- Scegliere il materiale sbagliato: Cause 30% di problemi

- Non si stringe abbastanza: Conduce a 15% di perdite

- Disadattamento della filettatura: Il 10% delle ghiandole non funziona.

Attenzione: Non utilizzare mai nastro adesivo o colla per far combaciare un pressacavo! Questo viola le regole di sicurezza.

10. Perché scegliere i pressacavi personalizzati CAGLAND

Noi di CAGLAND produciamo pressacavi che risolvono tutti questi problemi!

Cosa ci rende migliori:

- Dimensioni personalizzate: Realizziamo tutte le dimensioni necessarie

- Alta qualità: Tutte le ghiandole sono state testate prima della spedizione

- Consegna rapida: Ricevere l'ordine rapidamente

- Prezzi bassi: Risparmiare denaro senza perdere in qualità

- L'aiuto degli esperti: Vi aiutiamo a scegliere la ghiandola giusta

Da anni aiutiamo le aziende a risolvere i loro problemi con i cavi. I nostri pressacavi sono utilizzati in grandi progetti in tutto il mondo!

Storie di successo nella vita reale

Caso 1: Riparazione del centro dati

Un grande centro dati doveva gestire oltre 300 cavi. Hanno utilizzato i nostri pressacavi con codice colore. Questo ha ridotto i tempi di riparazione di 40%!

Caso 2: Piattaforma petrolifera offshore

Una piattaforma petrolifera aveva bisogno di bloccare i danni causati dall'acqua salata. Hanno utilizzato i nostri pressacavi IP68 in acciaio inox. Dopo 5 anni: zero guasti!

Caso 3: Controlli motore di fabbrica

Una fabbrica ha avuto problemi con i controlli dei motori. I nostri pressacavi di schermatura EMI hanno ridotto il rumore del segnale di 90%!

Come ordinare i pressacavi personalizzati di CAGLAND

Siete pronti a ottenere i pressacavi perfetti per il vostro lavoro? È facile!

- Misurare i cavi

- Nota le esigenze del filo

- Pensate a dove verranno utilizzati

- Contattate CAGLAND con questi dati

- Richiedete subito un preventivo gratuito!

FAQ sui pressacavi

D: Posso utilizzare lo stesso pressacavo per cavi armati e non armati? R: No! I cavi corazzati necessitano di speciali ghiandole che trattengono l'armatura.

D: Come faccio a sapere se la mia area è "pericolosa"? R: Se ci sono gas, polveri o sostanze chimiche che possono prendere fuoco, è pericoloso.

D: Posso riutilizzare i pressacavi? R: Non lo suggeriamo. Le guarnizioni si usurano e potrebbero non funzionare correttamente.

D: Qual è la differenza tra IP67 e IP68? R: Il grado di protezione IP67 può sopportare una breve permanenza in acqua. L'IP68 può rimanere sott'acqua per tutto il tempo.

Conclusione: Il giusto pressacavo fa la differenza

Scegliendo il giusto pressacavo si evitano grossi problemi prima che inizino! Con i pressacavi personalizzati di CAGLAND, otterrete:

- Adattamento perfetto per i cavi

- Protezione di lunga durata

- Connessioni sicure e affidabili

- Grandi risparmi di tempo e denaro

Non lasciate che dei cattivi pressacavi rovinino il vostro duro lavoro! Scegliete CAGLAND per tutte le vostre esigenze di pressacavi.

Avete bisogno di una soluzione di cablaggio completa? Consultate il nostro scatola di giunzione anche i prodotti!

Visita CAGLIARI per vedere tutte le nostre opzioni di pressacavi di alta qualità.