EMC Cable Gland

What Is It?

An is a special part that keeps wires safe. It stops bad signals from getting in. It also keeps water out.

How It Works

- UN metal spring inside touches the wire shield

- This makes a full circle of protection

- Just tighten the gland to get perfect shielding

- No need to cut the wire shield

What It’s Made Of

| Part | Materiale |

|---|---|

| Body | Stainless steel or brass |

| Seals | Rubber that lasts long |

| Spring | Stainless steel for strong grip |

Where You Can Use It

Our EMC glands work in many places:

- Oil and gas sites where things might blow up

- Wind and sun power plants

- Ships in salt water

- Big machines that shake a lot

- Phone towers and data rooms

- Clean rooms where foods and drugs are made

Why Pick Our Gland?

Keeps Bad Stuff Out

- Dust? No way in.

- Water? Stays dry.

- Bad signals? Blocked.

Works in Tough Spots

- Hot (up to +120°C)

- Cold (down to -60°C)

- Wet (IP68, IP69K rated)

- Rough (won’t break when shaken)

Easy to Put On

- Fast to set up

- No need to strip wires

- Saves time on big jobs

Sizes We Have

We have many sizes to fit your needs:

- M12, M16, M20, M25, M32 up to M100

- PG types too

- NPT if you need it

See These Too

Need more wire parts? Check these out:

- Metal Waterproof Cable Glands for tough jobs

- Plastic Waterproof Cable Glands for light use

- Multi-Hole Cable Glands for many wires

- Junction Boxes to join wires

Why People Trust Us

Big names like Amphenol, LAPP, E Pepperl+Fuchs use glands like ours. The EMC gland market is growing fast at 6.4% each year. More than $2.5 billion will be spent on these by 2030.

Get Yours Now

Don’t let bad signals mess up your work. Don’t let water get in your wires. Get our EMC cable glands now and keep things running smooth. Call us: +86 13773018938 E-mail: [email protected]

Inchiesta

Specifica

Product Specification

| Product Name | EMC anti magnetic cable gland |

| Modello | PG M NPT G |

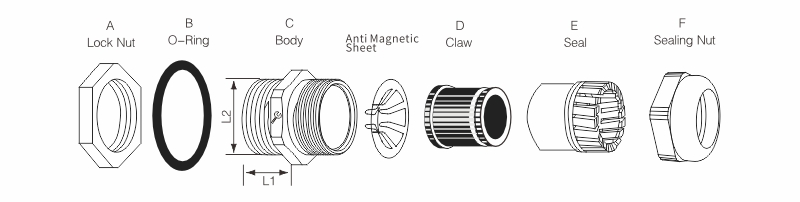

| Product Material | The tightening nut, main body, and nut parts are made of high-quality brass materials; The gripping claws, sealing rings, and gaskets are made of weather resistant nitrile rubber. |

| Temperature range | Static -40 ℃ to 100 ℃, instantaneous heat resistance to 120 ℃; Dynamic -20 ℃ to 80 ℃, instantly heat-resistant to 100 ℃. |

| Product design features | Special clamping claw and rubber component design, with a wide range of cable clamping and strong tensile strength |

| Product performance | Waterproof, dustproof, salt resistant, acid and alkali resistant, alcohol, grease and general solvents. |

| Protection level | IP66 IP68 |

| Fire resistance | UL94 V-2 |

| UV resistant | F1 |

| Environmental protection | Compliant with RoHs standards, halogen-free |

| Certificate | CE, RoHS, REACH |

| Cable range | Refer to the specification table for specific size specifications and display diagram |

Technical Parameter

| Modello | Gamma cavi (mm) | Thread O.D. L2 (mm) | Thread Length L1 (mm) | Spanner Size A & E (mm) |

|---|---|---|---|---|

| BPG7 | 3-6.5 | 12.5 | 7 | 14 |

| BPG7 | 2-5 | 12.5 | 7 | 14 |

| BPG9 | 4-8 | 15.2 | 8 | 17 |

| BPG9 | 2-6 | 15.2 | 8 | 17 |

| BPG11 | 5-10 | 18.6 | 8 | 20 |

| BPG11 | 3-7 | 18.6 | 8 | 20 |

| BPG13.5 | 6-12 | 20.4 | 8 | 22 |

| BPG13.5 | 5-9 | 20.4 | 8 | 22 |

| BPG16 | 10-14 | 22.5 | 8 | 24 |

| BPG16 | 6-12 | 22.5 | 8 | 24 |

| BPG19 | 12-16 | 25 | 9 | 27 |

| BPG19 | 7-12 | 25 | 9 | 27 |

| BPG21 | 13-18 | 28.3 | 9 | 30 |

| BPG21 | 9-16 | 28.3 | 9 | 30 |

| BPG25 | 15-22 | 32 | 10 | 35 |

| BPG25 | 13-18 | 32 | 10 | 35 |

| BPG29 | 18-25 | 37 | 10 | 40 |

| BPG29 | 13-20 | 37 | 10 | 40 |

| BPG36 | 22-33 | 47 | 11 | 50 |

| BPG36 | 20-26 | 47 | 11 | 50 |

| BPG42 | 32-38 | 54 | 12 | 57 |

| BPG42 | 25-31 | 54 | 12 | 57 |

| BPG48 | 37-44 | 59.3 | 12 | 64 |

| BPG48 | 29-35 | 59.3 | 12 | 64 |

| BPG63 | 42-52 | 72 | 14 | 78 |

| BPG63 | 32-40 | 72 | 14 | 78 |

| BM8 | 2-5 | 8 | 6 | 11 |

| BM8 | 1-2.5 | 8 | 6 | 11 |

| BM10 | 3-6.5 | 10 | 7 | 14 |

| BM10 | 1.5-3 | 10 | 7 | 14 |

| BM12 | 3-6.5 | 12 | 7 | 14 |

| BM12 | 1.5-3 | 12 | 7 | 14 |

| BM16 | 4-8 | 16 | 8 | 18 |

| BM16 | 2-6 | 16 | 8 | 18 |

| BM18 | 5-10 | 18 | 8 | 20 |

| BM18 | 3-7 | 18 | 8 | 20 |

| BM20 | 6-12 | 20 | 8 | 22 |

| BM20 | 5-9 | 20 | 8 | 22 |

| BM22 | 10-14 | 22 | 8 | 24 |

| BM22 | 7-12 | 22 | 8 | 24 |

| BM25 | 12-16 | 25 | 9 | 27 |

| BM25 | 10-12 | 25 | 9 | 27 |

| BM27 | 13-18 | 27 | 9 | 30 |

| BM27 | 9-6 | 27 | 9 | 30 |

| BM30 | 13-18 | 30 | 9 | 32 |

| BM30 | 9-6 | 30 | 9 | 32 |

| BM32 | 15-22 | 32 | 10 | 35 |

| BM32 | 13-18 | 32 | 10 | 35 |

| BM36 | 18-25 | 36 | 10 | 40 |

| BM36 | 13-20 | 36 | 10 | 40 |

| BM40 | 22-30 | 40 | 11 | 45 |

| BM40 | 20-26 | 40 | 11 | 45 |

| BM42 | 25-33 | 42 | 11 | 50 |

| BM42 | 20-26 | 42 | 11 | 50 |

| BM50 | 32-38 | 50 | 12 | 57 |

| BM50 | 25-31 | 50 | 12 | 57 |

| BM63 | 37-44 | 63 | 14 | 68 |

| BM63 | 29-35 | 63 | 14 | 68 |

| BM72 | 42-52 | 72 | 15 | 78 |

| BM72 | 32-40 | 72 | 15 | 78 |

| BM75 | 42-52 | 75 | 15 | 78 |

| BM75 | 32-40 | 75 | 15 | 78 |

| BM80 | 55-62 | 80 | 16 | 86 |

| BM80 | 45-52 | 80 | 16 | 86 |

| BM88 | 65-70 | 88 | 18 | 94 |

| BM88 | 55-60 | 88 | 18 | 94 |

| BM100 | 78-84 | 100 | 20 | 110 |

| BM100 | 68-74 | 100 | 20 | 110 |

| BNPT 1/4″ | 3-6.5 | 13.6 | 7 | 14 |

| BNPT 1/4″ | 1.5-3 | 13.6 | 7 | 14 |

| BNPT 3/8″ | 4-8 | 17 | 8 | 18 |

| BNPT 3/8″ | 2-6 | 17 | 8 | 18 |

| BNPT 1/2″ | 6-12 | 21.2 | 8 | 22 |

| BNPT 1/2″ | 5-9 | 21.2 | 8 | 22 |

| BNPT 3/4″ | 13-18 | 26.5 | 9 | 30 |

| BNPT 3/4″ | 9-16 | 26.5 | 9 | 30 |

| BNPT 1″ | 18-25 | 33.2 | 10 | 40 |

| BNPT 1″ | 13-20 | 33.2 | 10 | 40 |

| BNPT 1-1/4″ | 22-33 | 41.9 | 11 | 45 |

| BNPT 1-1/4″ | 18-25 | 41.9 | 11 | 45 |

| BNPT 1-1/2″ | 32-38 | 48 | 13 | 52 |

| BNPT 1-1/2″ | 20-26 | 48 | 13 | 52 |

| BNPT 2″ | 37-44 | 60 | 14 | 64 |

| BNPT 2″ | 29-35 | 60 | 14 | 64 |

| BNPT 2-1/2″ | 42-52 | 72.6 | 15 | 78 |

| BNPT 2-1/2″ | 32-40 | 72.6 | 15 | 78 |

| BNPT 3″ | 65-70 | 88.6 | 15 | 94 |

| BNPT 3″ | 55-60 | 88.6 | 15 | 94 |

| BG1/4″ | 3-6.5 | 13.1 | 7 | 14 |

| BG1/4″ | 1.5-3 | 13.1 | 7 | 14 |

| BG3/8″ | 4-8 | 16.6 | 8 | 18 |

| BG3/8″ | 2-6 | 16.6 | 8 | 18 |

| BG1/2″ | 6-12 | 20.9 | 8 | 22 |

| BG1/2″ | 5-9 | 20.9 | 8 | 22 |

| BG3/4″ | 13-18 | 26.4 | 9 | 30 |

| BG3/4″ | 9-16 | 26.4 | 9 | 30 |

| BG1″ | 18-25 | 33.2 | 10 | 40 |

| BG1″ | 13-20 | 33.2 | 10 | 40 |

| BG11/4″ | 18-25 | 41.9 | 11 | 50 |

| BG11/4″ | 13-20 | 41.9 | 11 | 50 |

| BG11/2″ | 22-32 | 47.8 | 13 | 57 |

| BG11/2″ | 20-26 | 47.8 | 13 | 57 |

| BG2″ | 37-44 | 59.6 | 14 | 64 |

| BG2″ | 29-34 | 59.6 | 14 | 64 |

| BG2 1/2″ | 42-52 | 75.1 | 15 | 78 |

| BG2 1/2″ | 32-40 | 75.1 | 15 | 78 |

| BG3″ | 65-70 | 87.8 | 15 | 94 |

| BG3″ | 55-60 | 87.8 | 15 | 94 |

Domande frequenti sul pressacavo

Non abbiamo fissato un MOQ minimo, personalizziamo i prodotti in base alle esigenze del cliente. In teoria, possiamo soddisfare diversi requisiti MOQ dei clienti, ma diversi MOQ avranno costi diversi.

Normalmente il nostro tempo di consegna è di 1 ~ 2 settimane per la produzione in lotti. Per casi urgenti, possiamo migliorarlo in 3 ~ 7 giorni.

Abbiamo bisogno della dimensione, del colore, del filo, del materiale, della certificazione e altre applicazioni saranno utili.

Abbiamo certificati CE, TUV e UL.

Certamente, possiamo fornirti i campioni standard gratuiti in base alle tue esigenze.