Nylon Conduit Connector BG

Hi! We make nylon hose connectors. They join hoses together. Our connectors are strong. They work in hot and cold places. You can use them for many jobs.

Why Pick Our Nylon Hose Connectors?

Our connectors are good because:

- They are strong

- They are light

- They do not rust

- They fit many hose types

- They last a long time

What Our Nylon Hose Connectors Can Do

Our nylon connectors work well in many places:

| Where to Use | What They Do |

|---|---|

| Cars | Join fuel lines, brake hoses, coolant tubes |

| Factories | Connect air tools and water pipes |

| Farms | Help with water and spray systems |

| Solar panels | Keep wires safe in sun and rain |

| Home projects | Make fixing pipes easy |

Types of Nylon Hose Connectors We Make

We have many types to pick from:

1. Quick-Connect Fittings

These snap on fast! No tools needed. Just push and click. They save you time.

2. Thread Types

We make many thread types:

- BSPP

- BSPT

- NPT

- Metric

3. Sizes

Our connectors come in all these sizes:

- 1/4 inch

- 3/8 inch

- 1/2 inch

- 3/4 inch

- 1 inch

Cool Facts About Our Connectors

- Work in very hot or cold places (-40°F to +200°F)

- Can handle high pressure (up to 250 PSI)

- Do not break in sun or rain

- Work with water, oil, gas, and more

- Very light but very strong

Where You Can Use Our Connectors

For Cars and Trucks

Our nylon hose connectors work great in cars! They connect:

- Fuel lines

- Brake hoses

- Cooling systems

They stay strong even when the car shakes.

For Air Tools

Do you use air tools? Our connectors help:

- Keep air from leaking

- Connect tools fast

- Handle high air pressure

Check out our plastic water proof cable gland too!

For Farms

Farmers love our connectors because they:

- Work with water and farm sprays

- Do not break in hot sun

- Can be fixed fast

- Last many seasons

For Solar Power

Solar panel systems need good connectors. Ours:

- Keep sun from breaking them

- Hold wires safe and tight

- Work for many years

- Can handle rain and heat

For Home Jobs

Fix things at home with our connectors:

- Join garden hoses

- Fix leaky pipes

- Connect shop tools

- Last for years

What Makes Our Nylon Connectors Special

Strong Materials

We use good nylon types:

- Nylon 6/6

- PA11

- PA12

These stand up to oil, gas, and most chemicals.

Push-to-Connect Design

Our quick-connect nylon fittings are so easy:

- Cut your hose end straight

- Push into connector

- Pull to check it’s tight

- Done!

No wrenches or tools needed!

Works in Tough Places

Our connectors can handle:

- Very hot days

- Very cold nights

- Wet places

- Shaky machines

- Strong chemicals

Want something for wet places? See our metal water proof cable gland line!

Size Chart for Our Nylon Hose Connectors

| Size | Works Best For | Max Pressure | Good With |

|---|---|---|---|

| 1/4″ | Small air lines | 250 PSI | Air tools |

| 3/8″ | Medium jobs | 200 PSI | Water, air |

| 1/2″ | Home and shop | 175 PSI | Most uses |

| 3/4″ | Big water lines | 150 PSI | Water systems |

| 1″ | High flow needs | 125 PSI | Big jobs |

Why Customers Like Our Connectors

Our customers say:

“These connectors snap on so fast! No leaks after a year.”

“I use them in my farm and they handle all weather.”

“Much lighter than metal but just as strong.”

More Than Just Connectors

We don’t just make nylon hose connectors! We also make:

- Cable glands – keep wires safe

- Multi hole cable gland – for many wires at once

- Junction boxes – connect wires safely

- Cable gland adaptors – change sizes as needed

- Conduit fittings – for electrical jobs

Need to join wires? Look at our Boîte de dérivation products!

Custom Connectors Just For You

Do you need special connectors? We can make them!

- Tell us what you need

- We draw it up

- You check it

- We make it for you

This is our OEM/ODM service. We make what YOU need.

Putting In Your Nylon Hose Connector

It’s easy to use our connectors:

- Cut your hose end flat and clean

- Mark how far to push it in

- Push hose into the connector

- Pull to test it’s tight

- Turn on your system slow to check for leaks

Tips For Using Nylon Hose Connectors

- Don’t use where it’s hotter than 200°F

- Check if your liquids are safe with nylon

- Don’t bend hoses right at the connector

- Use the right size for your job

Why Buy From Us?

- We test all connectors before shipping

- We use top materials only

- We can make custom sizes

- Our prices are fair

- We ship fast

Ready to Order?

Call us or email for:

- Free samples

- Price list

- Custom designs

- Big orders

- Help picking the right parts

Our team helps you get just what you need.

See our full line of Conduit Connectors & Fittings on our website!

Connect With Us

Have questions? Need help? Want to order?

- Call: +86 137 7301 8938

- Email: [email protected]

- Visit: www.cagland.com

We’re here to help you get the right nylon hose connectors for your job!

Demande

spécification

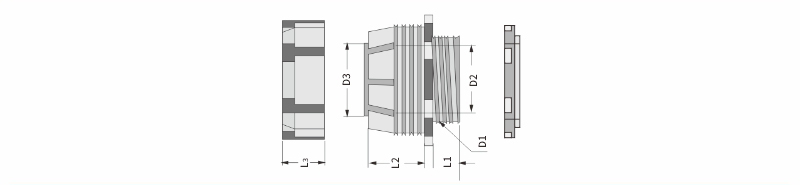

Product Specification

| Product Name | BG series corrugated pipe joint |

| Product Material | Using nylon PA66,94V-2. |

| Product color | White, black, and gray. |

| Product Usage | Fix the hose on the control panel of the machine and equipment. |

| Product application | 1. The installation body needs to be pre drilled on the panel; 2. The hose passes through the nut and the hose passes through the clamping claw; 3. Fix the nut“ |

| Product specifications | Please refer to the specification and size diagram for specific models |

| Technical Parameters | |||||||

| Modèle | D1 (mm) | D2 (mm) | D3 (mm) | L1 (mm) | L2 (mm) | L3 (mm) | Suitable Flexible Pipe |

| BG-10 | 14.4 | 6.3 | 7.5 | 9.7 | 18.5 | 15.9 | BG-10P |

| BG-16 | 15.9 | 11 | 10.8 | 10 | 17.9 | 15.7 | BG-16P |

| BG-18 | 16 | 11.1 | 13.3 | 9.7 | 18.6 | 15.9 | BG-18P (3/8”) |

| BG-20 | 19.2 | 15 | 14.7 | 10 | 17.7 | 16 | BG-20P |

| BG-22 | 20 | 15.4 | 17.2 | 9.8 | 17.6 | 16.3 | BG-22P (1/2”) |

| BG-25 | 25 | 18.9 | 19.8 | 11.4 | 23.6 | 20.6 | BG-25P (3/4”) |

| BG-32 | 31.2 | 26 | 24.3 | 12 | 22.8 | 20.6 | BG-32P |

| BG-34 | 32 | 26.8 | 28.6 | 11.3 | 23.3 | 20.7 | BG-34P (1”) |

| BG-40 | 37.5 | 31.5 | 31.6 | 11.3 | 23.6 | 20.7 | BG-40P |

| BG-42 | 40 | 32.7 | 34.8 | 11.5 | 23.3 | 20.8 | BG-42P (1”) |

| BG-48 | 44 | 37.5 | 40.5 | 12.6 | 22.3 | 20.7 | BG-48P |

| BG-50 | 44 | 37.5 | 39.5 | 12.6 | 21.6 | 20.7 | BG-50P |

Foire aux questions sur le presse-étoupe

Nous n'avons pas fixé de MOQ minimum, nous personnalisons les produits en fonction des besoins des clients. En théorie, nous pouvons répondre aux différentes exigences MOQ des clients, mais différents MOQ auront des coûts différents.

Normalement, notre délai de livraison est de 1 à 2 semaines pour la production par lots. Pour les cas urgents, nous pouvons l'améliorer en 3 à 7 jours.

Nous avons besoin de la dimension, de la couleur, du fil, du matériau, de la certification et d'autres applications seront utiles.

Nous avons des certificats CE, TUV et UL.

Certes, nous pouvons vous fournir les échantillons standard gratuits selon vos besoins.