Indholdsfortegnelse

Hvad er en kabelforskruning? Din enkle guide til at holde ledningerne sikre

Ledninger bærer strøm. Strøm får ting til at fungere! Som lys, tv og store maskiner. Men ledninger kan komme til skade. Problem: Vand, støv eller træk kan ødelægge ledninger. Det er ikke godt. Ødelagte ledninger betyder, at ting holder op med at virke. Det kan endda være farligt! Der kan opstå gnister. Åh, nej, nej!

Rør rundt: Forestil dig, at din fabrik går i stå. Intet arbejde bliver udført. Penge går tabt. Eller tænk på et skib. Hvis ledningerne går i stykker, mister skibet måske strømmen på det store hav! Det er skræmmende. På steder som miner eller oliefabrikker kan en ødelagt ledning forårsage en stor brand eller et brag! Vi ønsker ikke disse dårlige ting. Vi er nødt til at holde ledningerne sikre.

Løsning: Det er der kabelforskruninger komme ind! De er som små bodyguards for ledninger. A kabelforskruning er et særligt stik. Det holder ledningen tæt. Det forsegler enden af ledningen. Det forbinder ledningen sikkert til kasser eller maskiner. De kaldes også greb med ledning, kabelstik, Kabelfittingseller mekaniske kabelindføringsanordninger. De gør et super vigtigt stykke arbejde.

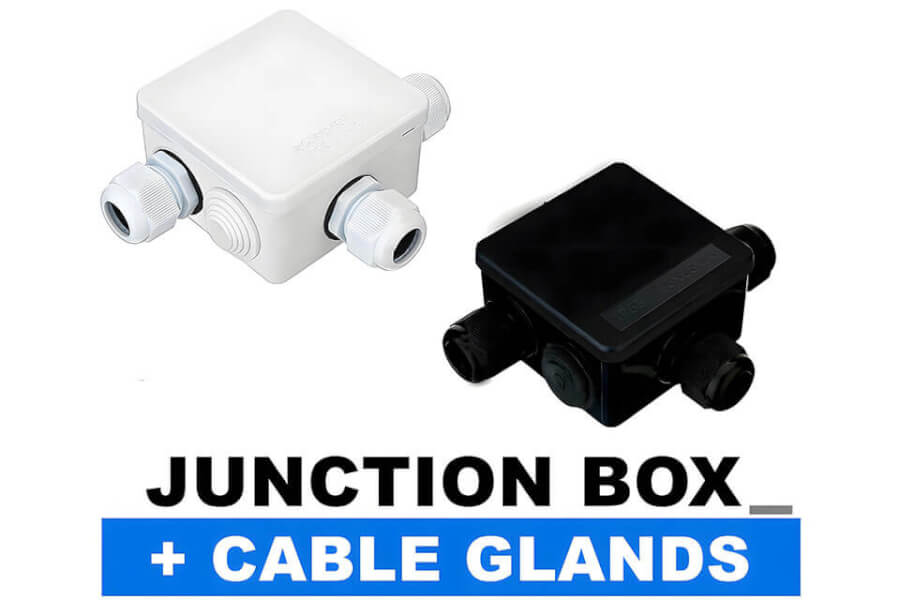

Vi er CAGLAND, en producent af kabelforskruninger i Kina. Vi laver stærke kabelforskruninger til at holde din sikre ledninger. Vi laver mange slags, f.eks. Vandtætte kabelforskruninger af metal og Vandtætte kabelforskruninger af plast. Vi laver endda kabelforskruninger med flere huller til mange ledninger! Vi laver også sikre Samledåser til at forbinde ledninger. Vi vil gerne hjælpe dig med at stoppe problemer med ledninger, før de opstår.

1. Hvordan ser en kabelforskruning ud? (Vigtige dele)

En kabelforskruning ser lille ud. Men den har vigtige dele. Tænk på den som et lille puslespil. Alle dele passer sammen.

Problem: Hvis du ikke kender delene, bruger du måske ikke kirtlen rigtigt. En usikker ledning er som at lade døren stå ulåst!

Rør rundt: Hvis man bruger den forkerte del eller sætter den forkert sammen, er ledningen ikke sikker. Vand kan snige sig ind. Støv kan tilstoppe tingene. Ledningen kan glide ud! Det fører tilbage til ødelagte maskiner og fare.

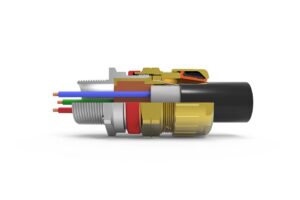

Løsning: Lad os lære delene at kende! At kende delene hjælper dig med at se, hvordan de beskytter ledningen. De fleste kabelforskruninger har disse hoveddele:

- Kroppen: Dette er hovedstykket. Det er ofte formet som et rør. Det har gevind som en skrue. Ledningen går gennem midten af kroppen. Kroppen skrues fast i maskinen eller kassen.

- Forseglingsringen: Dette er en blød ring. Som en lille gummidonut. Den passer rundt om ledningen inde i kroppen. Dens opgave er at lave en tæt forsegling. Intet vand eller støv kan passere! Nogle kirtler har to sæler. Disse er dobbelt kompression kirtler. De giver ekstra sikkerhed.

- Kompressionsmøtrikken: Det er som en hætte. Den skrues på kroppen. Når du strammer møtrikken, skubber den til tætningsringen. Ringen klemmer på ledningen. Det holder ledningen tæt og får forseglingen til at fungere.

- Skiver: Nogle gange er der flade ringe, som kaldes skiver. De hjælper med at skabe en god pasform og tætning.

- Armor Clamp (til specielle ledninger): Nogle ledninger har metalpanser, som en ridderdragt! Disse ledninger har brug for Pansrede kabelforskruninger. Disse kirtler har ekstra dele til at holde rustningen tæt. Dette bruges ofte sammen med SWA (pansret stålkabel) kabel.

Se på delene nedenfor:

| Delens navn | Hvad det gør | Hvorfor det er vigtigt |

|---|---|---|

| Kroppen | Har plads til alt, fastgøres til kassen | Holder kirtlen sikker |

| Tætningsring | Klemmer på kablet | Stopper vand og støv (vandtæt) |

| Kompressionsmøtrik | Strammer forseglingen | Gør grebet stærkt |

| Skiver | Hjælp med at lave en tæt pasform | Forbedrer forseglingen |

| Panserklemme | Holder rustning af metaltråd (på pansrede kirtler) | Beskytter særligt stærke ledninger |

Hos CAGLAND sørger vi for, at alle disse dele passer perfekt. Vores kirtler er nemme at sætte sammen. De skaber en stærk og sikker forbindelse hver gang.

2. Hvordan fungerer en kabelforskruning? (Nemme trin)

Okay, vi kender delene. Og nu.., Hvordan fungerer kabelforskruninger?? Det er ganske enkelt! De klemmer og holder på ledningen.

Problem: Ledninger kan blive trukket eller snoet. Dette kaldes belastning. Belastning kan ødelægge de små metaldele inde i ledningen. Åbninger, hvor ledninger går ind i kasser, lukker også dårlige ting som vand ind.

Rør rundt: Forestil dig en ledning, der er trukket løs fra en maskine. Maskinen stopper. Måske flyver der gnister! Eller tænk på regn, der trænger ind i en udendørs elboks. Zapp! Strømmen går. Det koster tid og penge at reparere det. Det er en stor smerte.

Løsning: En kabelforskruning løser disse problemer! Den holder ledningen tæt (ingen belastningsaflastning købes separat) og forsegler hullet. Sådan fungerer det trin for trin:

- Gør dig klar: Først gør du ledningen klar. Det kan være nødvendigt at trimme enden lidt.

- Sæt dele på: Du skubber kompressionsmøtrikken og derefter tætningsringen på ledningen.

- Ledning gennem kroppen: Du skubber ledningen gennem hoveddelen af kabelforskruning.

- Sæt kroppen fast: Du skruer kirtlens krop ind i hullet på maskinen eller på samledåse.

- Spænd møtrikken: Nu skruer du kompressionsmøtrikken på kroppen. Når du strammer den, sker der noget magisk!

- Klem! Møtrikken skubber til tætningsringen. Den bløde ring klemmer sig fast omkring ledningen.

- Seal! Ringen forsegler mellemrummet. Ikke mere plads til vand eller støv! Den er støvtæt og vandtæt.

- Tag fat! Den sammenpressede ring griber også hårdt fat i ledningen. Nu kan du ikke længere trække ledningen ud. Den belastning er væk!

- Ekstra sikkerhed (dobbelt kompression): Til virkelig hårde opgaver, som med Pansrede kabelforskruninger eller på risikable steder, dobbelt kompression kirtler tilføjer en anden forsegling. Dette forsegler ofte den indre del af ledningen og det ydre panser. Super sikker!

Tænk på det som at binde din sko. Du trækker i snørebåndene (strammer møtrikken), og skoen holder din fod fast (griber fat i ledningen).

CAGLAND designer kirtler, der er lette at spænde. Vores tætninger klemmer perfekt. Vores greb er stærkt. Vi sørger for, at dine ledninger bliver siddende og er sikre.

3. Hvilke slags kabelforskruninger findes der?

Ikke alle ledninger er ens. Ikke alle steder er ens. Så der findes forskellige slags kabelforskruninger!

Problem: At bruge den forkerte type kabelforskruning er som at gå med sandaler i sneen! Det fungerer bare ikke rigtigt. Ledningen er måske ikke sikker.

Rør rundt: Hvis du bruger en simpel plastikforskruning, hvor du har brug for en superstærk metalforskruning, kan den gå i stykker! Hvis du bruger en normal forskruning på et meget vådt sted, vil der trænge vand ind. Hvis man vælger forkert, svigter beskyttelsen. Det fører til ødelagte elektriske systemer og dyre reparationer.

Løsning: Vælg den rigtige kabelforskruning til jobbet! Hos CAGLAND laver vi mange typer. Lad os se på nogle af de mest almindelige:

Kabelforskruninger af plast:

- Fremstillet af stærk plast (som nylon).

- God til mange hverdagsbrug.

- De ruster ikke! Perfekt til våde steder, eller hvor der bruges kemikalier.

- God værdi.

- CAGLAND laver: Høj kvalitet Vandtætte kabelforskruninger af plast der tilbyder stor forsegling.

Kabelforskruninger af metal (messing, rustfrit stål):

- Lavet af metal, f.eks. messing eller skinnende rustfrit stål.

- Superstærk og hårdfør.

- Messing er godt til de fleste maskiner og værktøjer. Ruster ikke så let.

- Rustfrit stål er det hårdeste! Det bekæmper rust og kemikalier virkelig godt. Perfekt til fødevarefabrikker eller barske steder.

- CAGLAND laver: Robust Vandtætte kabelforskruninger af metal af messing og rustfrit stål. Bygget til at holde!

Pansrede kabelforskruninger:

- Særlige kirtler til særlige ledninger. Disse ledninger har metalpanser (SWA) for ekstra beskyttelse.

- Disse kirtler har ekstra dele til at gribe sikkert fat i panseret.

- Bruger ofte dobbelt kompression for den bedste forsegling og det bedste greb.

- Bruges på fabrikker, byggepladser og til hårde udendørs opgaver.

Vandtætte kabelforskruninger:

- Designet til at holde vand helt ude!

- De har særlige tætninger, ofte lavet af gummi.

- De har en IP-klassificering. En høj vurdering som IP68 betyder, at de endda kan gå under vandet i et stykke tid! Vores data viser, at IP68-kirtler kan klare 1,5 meters dybde.

- Perfekt til udendørs brug, både og våde fabrikker.

- CAGLAND laver: Både metal- og plastkirtler, der er meget vandtæt.

Brandsikre/eksplosionssikre kabelforskruninger:

- Supersikre kirtler til farlige steder. Ligesom olieraffinaderier, minedrift områder eller kemiske anlæg.

- De forhindrer gnister i at komme ud og forårsage brand eller brag! Data tyder på, at de reducerer eksplosionsrisikoen med 95% i disse områder.

- Bruger ofte dobbelt kompression sæler.

- Skal opfylde særlige sikkerhedsregler som ATEX eller IECEx.

Kabelforskruninger med flere huller:

- Problem: Nogle gange har man mange ledninger, der går ind i en boks. At bruge en forskruning til hver ledning optager plads!

- Rør rundt: En rodet kasse med for mange huller kan være svær at arbejde med og mindre sikker.

- Løsning: Kabelforskruninger med flere huller! Disse smarte kirtler har én krop, men huller til to eller flere ledninger. Sparer plads! Holder orden i tingene.

- CAGLAND laver: Praktisk kabelforskruninger med flere huller for at forenkle din ledningsføring.

Her er en hurtig guide:

| Kirteltype | Bedst til | Nøglefunktion | Hvad laver CAGLAND? |

|---|---|---|---|

| Plastik | Almindelig brug, våde områder, kemikalier | Korrosionsbestandig | Ja! |

| Metal (messing/stål) | Maskiner, hårde job, høj varme | Stærk, holdbar | Ja! |

| Pansret | SWA kabler, industriområder | Greb rustning | Spørg os! |

| Vandtæt (IP68) | Udendørs, marine, våde fabrikker | Holder vand ude | Ja! |

| Flammesikker | Farlige områder (olie, gas, miner) | Forhindrer eksplosioner | Spørg os! |

| Multi-hul | Kører flere kabler ind i én boks | Sparer plads, ryddelig | Ja! |

At vælge den rigtige type er nøglen! CAGLAND kan hjælpe dig med at vælge den perfekte kabelforskruning til dine behov.

4. Hvor bruger vi kabelforskruninger?

Der er kabelforskruninger overalt! Det er bare ikke sikkert, du ser dem. De arbejder hårdt bag kulisserne.

Problem: Uden kabelforskruninger, elektriske systemer mange steder ville svigte hurtigt. Maskiner ville gå i stykker. Lyset ville gå ud. Sikkerheden ville være lav.

Rør rundt: Tænk på et hospital. Ledninger driver livreddende maskiner! De skal være sikker. Tænk på et travlt fabriksgulv. Masser af bevægelse, støv og måske vand. Ledninger har brug for stærke beskyttelse. At ignorere dette fører til sammenbrud og fare.

Løsning: Kabelforskruninger giver den vigtige beskyttelse mange steder:

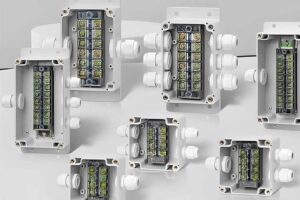

- Kontrolpaneler og bokse: Det er maskinernes hjerner. Masser af ledninger går ind og ud. Kabelforskruninger forsegler hullerne. De forhindrer, at der kommer støv på de små elektriske dele. De holder ledningerne pæne og sikre inde i samledåse.

- Fabrikker og maskiner: Fabrikker har masser af maskiner. Ledninger løber overalt. Kabelforskruninger beskytter ledningerne mod vibrationer, olie, støv og vand. De holder maskinerne kørende. Metal kabelforskruninger bruges ofte her.

- Udendørs belysning og skilte: Gadelamper, havelamper, store skilte. De er ude i regn, blæst og sol. Vandtætte kabelforskruninger (f.eks. IP68) er et must! De holder vandet ude, så lyset forbliver tændt.

- Skibe og både (marine): Både er altid i nærheden af vand! Saltvand er ekstra hårdt for metal. Særligt vandtæt og korrosionsbestandig Kabelforskruninger (som rustfrit stål eller specialplast) er nødvendige for at beskytte ledninger på skibe. Data viser, at de giver 100% beskyttelse mod saltvandsskader.

- Farlige områder: Steder som olieraffinaderier, gasanlæg, minedrift tunneler og kemiske fabrikker har støv eller gas, der kan bryde i brand eller eksplodere. Særlige brandsikre kabelforskruninger bruges her. De slutter tæt for at forhindre gnister i at slippe ud. Sikkerhed er nummer et! Disse har ofte brug for ATEX eller IECEx godkendelse.

- Byggepladser: Der bruges masser af midlertidig strøm. Ledninger løber hen over jorden. Hårdføre, ofte Pansrede kabelforskruningerbruges til at håndtere de barske forhold.

- Vedvarende energi: Solpaneler og vindmøller er udendørs. De har brug for vejrbestandig og pålidelige kabelforskruninger, der kan klare sol, regn og vind i mange år.

CAGLAND leverer kirtler til alle disse opgaver. Fra simple kasser til hårde farlige områder. Vi forstår, at forskellige steder har brug for forskellige slags beskyttelse.

5. Sådan vælger du den BEDSTE kabelforskruning til dine behov

Okay, du ved, hvad kirtler er, og hvor de sidder. Men hvordan vælger du den den rigtige?

Problem: At vælge den forkerte kirtelstørrelse eller det forkerte materiale kan give store problemer. For lille? Ledningen vil ikke passe. For stor? Tætningen virker ikke. Forkert materiale? Det kan gå i stykker eller ruste.

Rør rundt: Forestil dig at installere hundredvis af kirtler og så opdage, at de lækker, fordi de har den forkerte størrelse! Eller forestil dig, at en pakdåse svigter i en kritisk maskine, fordi plasten ikke kan klare varmen. Det spilder tid og penge og skaber risiko. Det er frustrerende!

Løsning: Vælg omhyggeligt! Tænk over disse ting:

Hvilken slags ledning (kabel)?

- Er det en normal rund ledning?

- Er den flad?

- Har den metalpanser (SWA)? Det kræver en armeret kabelforskruning.

- Hvad er ledningen lavet af (plastik, gummi)? Dette hjælper med at vælge kirtelmaterialet.

Hvor stor er ledningen?

- Du skal have en hulstørrelse på kirtlen, der passer til trådens udvendige tykkelse (diameter). Ikke for stramt, ikke for løst. Forskruninger findes i mange størrelser. Mål din ledning!

Hvor vil den blive brugt?

- Indenfor eller udenfor? Udenforliggende behov vejrbestandig / vandtæt kirtler.

- Vådt eller tørt? Våde steder har brug for høj IP-klassificering (som IP68). Tørre indendørs steder kan bruge enklere kirtler.

- Varmt eller koldt? Nogle plasttyper bliver bløde i varmen. Metal håndterer varme bedre.

- Kemikalier eller salt? Behov korrosionsbestandig materialer som rustfrit stål eller specialplast. Vores data viser, at rustfrit stål modstår syre godt.

- Farligt område? Har brug for noget særligt brandsikker kirtler (ATEX/IECEx-certificeret).

Hvilket materiale skal kirtlen være af?

- Plastik: God til almindelig brug, våde områder (ingen rust).

- Messing: Stærk, god til de fleste maskiner, modstår rust godt.

- Rustfrit stål: Den hårdeste, bedst til kemikalier, fødevareområder og meget våde steder.

Hvilken slags hul passer den ind i?

- Kirtelhuset har gevind (som en skrue). Sørg for, at gevindtypen (f.eks. metrisk eller NPT) passer til hullet i din kasse eller maskine.

Har du brug for særlige funktioner?

- Dobbelt kompression? For ekstra sikkerhed, især med rustning eller på vanskelige steder.

- Aflastning ved overanstrengelse? Alle kirtler giver noget, men nogle er designet til ekstra stærkt greb.

- Jordforbindelse? Metalforskruninger kan hjælpe med at jorde systemet af hensyn til den elektriske sikkerhed.

CAGLAND er her for at hjælpe! Som en top producent af kabelforskruninger i KinaVi kender kirtler. Fortæl os om din ledning, og hvor du vil bruge den. Vi kan hjælpe dig med at finde det perfekte match fra vores brede sortiment, herunder Vandtætte kabelforskruninger af metal, Vandtætte kabelforskruninger af plast, og kabelforskruninger med flere huller. At vælge rigtigt sparer dig for problemer senere!

6. Sæt kabelforskruninger i (installation) og hold dem ved lige (vedligeholdelse)

Du har valgt den rigtige kirtel! Nu skal du sætte den rigtigt i. Og tjekke den nogle gange.

Problem: Det er en almindelig fejl at sætte en kirtel forkert i! Data tyder på, at 70% af lækager i kirtler sker, fordi de ikke blev installeret rigtigt[^8]. Hvis man strammer for meget eller for lidt, opstår der problemer.

Rør rundt: En dårligt installeret pakdåse vil ikke tætne ordentligt. Der trænger vand ind. Der kommer støv ind. Ledningen glider måske. Alt det omhyggelige valg er spildt! Den beskyttelse fejler. Det kan føre til systemfejl, lige når du har allermest brug for det. Vedligeholdelse virker kedeligt, men hvis man ignorerer det, kan det føre til pludselige afbrydelser.

Løsning: Følg trinene! Vær forsigtig. Tjek dit arbejde.

Installationstrin (simpel version):

- Sikkerhed først! Sluk for strømmen, før du arbejder med ledninger.

- Gør kablet klar: Afisoler forsigtigt det yderste lag af ledningen, hvis det er nødvendigt. Afisoler kun så meget, som kirtlen har brug for. Skær ikke i de indre ledninger!

- Dele på kabel: Skub forskruningsdelene på kablet i den rigtige rækkefølge (normalt først møtrik, så pakning osv.).

- Kabel gennem hul: Skub kablet gennem hullet i boksen eller maskinen.

- Sæt kirtelkroppen på: Skru kirtelhuset ind i hullet. Sørg for, at det sidder fast. Brug en spændeskive, hvis det er nødvendigt.

- Indsæt kabel: Skub kablet gennem forskruningen, indtil det sidder på det rigtige sted.

- Spænd møtrikken: Skru kompressionsmøtrikken på kroppen. Spænd den godt fast med det rigtige værktøj (f.eks. en skruenøgle).

- Stram ikke for meget! Det kan knuse ledningen eller beskadige forseglingen.

- Stram ikke for meget! Forseglingen vil ikke fungere, og ledningen vil ikke blive holdt fast.

- Følg producentens råd, hvis de angiver en tilspændingskraft (moment).

- Tjek: Træk forsigtigt i kablet. Føles det sikkert? Kig på forseglingen. Ser den jævnt klemt ud?

- Testning: Ved vigtige opgaver skal du teste forbindelsen for at sikre, at den fungerer sikkert.

Tips til vedligeholdelse:

- Se her: Tjek kirtlerne af og til. Se efter revner, rust eller skader. Er møtrikken stadig stram?

- Mærk efter: Sidder kablet stadig godt fast?

- Ren: Hold kirtlerne rene, især i snavsede områder.

- Udskift om nødvendigt: Hvis en kirtel ser beskadiget ud, eller tætningen virker slidt, skal den udskiftes. Vent ikke på, at den svigter! Tætninger kan blive gamle og hårde.

God Installation og enkel vedligeholdelse Sørg for, at dine kabelforskruninger bliver ved med at gøre deres arbejde i lang, lang tid. CAGLAND-forskruninger er lavet til nem installation og lang levetid.

7. Spørgsmål, folk stiller om kabelforskruninger (FAQ)

Folk stiller ofte spørgsmål om kabelkirtler. Her er nogle af de mest almindelige:

Q: Kan jeg bruge én forskruning til mere end én ledning?

- A: Som regel ikke. De fleste kirtler er designet til en tråd for at få den bedste forsegling og det bedste greb. Problem: Hvis man sætter to ledninger i et enkelt hul, vil det ikke tætne rigtigt. Rør rundt: Lækager og dårligt greb vil ske! Løsning: Brug en flerhuls kabelforskruning hvis du har brug for at føre flere ledninger gennem et indgangspunkt. CAGLAND laver disse!

Q: Kan jeg genbruge en kabelforskruning?

- A: Det er som regel anbefales ikke. Problem: Når du strammer en kirtel, bliver tætningen presset i form. Rør rundt: Hvis du tager den af og prøver at genbruge den, er det ikke sikkert, at tætningen bliver presset ned på samme måde igen. Den kan blive utæt. Løsning: Det er sikrere at bruge en ny pakdåse til en ny forbindelse for at sikre en perfekt tætning. De er ikke særlig dyre.

Q: Hvor stramt skal møtrikken sidde?

- A: Stramt nok til at give en god forsegling og et godt greb, men ikke så stramt, at du beskadiger noget. Problem: For løs = lækager. For stramt = skader. Rør rundt: Begge dele fører til fiasko. Løsning: Følg producentens anvisninger, hvis de findes. Ellers skal du stramme godt til, indtil kablet føles sikkert, og møtrikken stopper let. Tving det ikke superhårdt. Her hjælper erfaring.

Q: Hvad betyder IP-klassificering (som IP68)?

- A: IP står for Ingress Protection. Det er en score for, hvor godt noget holder støv og vand ude. Det første tal er for støv (6 er støvtæt). Det andet tal er for vand (8 er beskyttet, selv når det er nedsænket under vandet i et stykke tid). Problem: Hvis du ikke kender IP-klassificeringen, kan det betyde, at du vælger en kirtel, der ikke er vandtæt nok. Rør rundt: Din udendørs elektronik bliver våd og går i stykker! Løsning: Se efter høje IP-klasser som IP67 eller IP68 til våde steder. CAGLAND tilbyder mange forskruninger med høj IP-klassificering.

Q: Hvad er forskellen på enkelt- og dobbeltkompressionskirtler?

- A: Enkeltkompressionsforskruninger har én hovedforsegling omkring kablets ydre lag. Dobbelt kompression kirtler har to tætninger. Ofte forsegler den ene det ydre lag, og den anden forsegler et indre lag eller kabelarmeringen. Problem: Det er måske ikke sikkert nok at bruge en enkelt forskruning, hvor der er brug for en dobbelt (som med nogle armerede kabler eller i farlige zoner). Rør rundt: Panseret sidder måske ikke rigtigt fast, eller forseglingen er måske ikke god nok til farlig gas. Løsning: Brug dobbelt kompression kirtler for ekstra sikkerhed og greb, især med SWA kabler eller i farlige områder.

8. Hvorfor vælge CAGLAND kabelforskruninger?

Ledninger har brug for beskyttelse. Dårlige forbindelser skaber store problemer. Kabelforskruninger er svaret!

Gennemgang af problemer: Uforseglede ledninger lukker støv og vand ind. Usikrede ledninger bliver trukket og går i stykker. Det fører til maskinsvigt, nedetid og sikkerhedsrisici.

Anmeldelse af Agitate: Tænk på omkostningerne - reparationer, tabt produktion, potentielle ulykker. Det er stressende og dyrt, når elektriske systemer mislykkes på grund af dårlig ledning beskyttelse.

Gennemgang af løsninger: Kabelforskruninger forsegler, griber og beskytter ledninger. De er afgørende for sikre, pålidelige forbindelser i hjem, fabrikker, skibe og selv i farlige miljøer. farlige områder.

Hvorfor CAGLAND?

Vi er en dedikeret producent af kabelforskruninger i Kina. Vi fokuserer på at lave pålidelige produkter af høj kvalitet.

- Vi laver det, du har brug for: Vi tilbyder et stort udvalg, herunder:

- Hårdfør Vandtætte kabelforskruninger af metal (Messing og rustfrit stål)

- Alsidig Vandtætte kabelforskruninger af plast (Nylon)

- Pladsbesparende kabelforskruninger med flere huller

- Trygt og sikkert Samledåser

- Materialer af høj kvalitet: Vi bruger gode materialer, der holder. Vores kirtler modstår Korrosion og slid.

- Stærke forseglinger: Vores kirtler er designet til fremragende tætning (vandtæt, støvtæt). Mange har høj IP-klassificering.

- Pålideligt greb: Vi sikrer en stærk belastningsaflastning for at forhindre udtrækning.

- Let at bruge: Vores kirtler er designet til at være ligetil Installation.

- Hjælpsom service: Vi kan hjælpe dig med at vælge den rigtige kabelforskruning til dit job.

Lad ikke kabelproblemer stoppe dig. Vælg CAGLAND for stærke, sikre og enkle kabelforskruningsløsninger. Sørg for, at strømmen flyder sikkert!